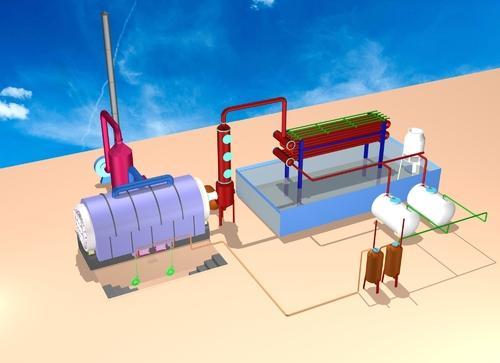

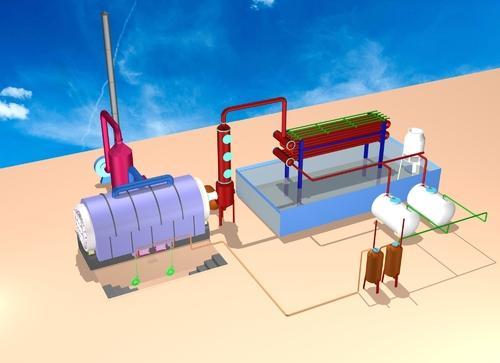

Anjali Exim with its unique renewable technology has come up with a concept of setting new standard in renewable energy that includes using of waste tyres as a raw material and producing green fuel oil, carbon black, steel and gas. With global warming and utilization of rubber, it has now become necessary to recycle the waste and convert it in fuel oil in such a way that it is environment friendly. This is a unique technology and can be change energy market scenario in a big way.

Features of the plant:

100% wastage tyre recycling is achieved (No churn left after the process)

No chemical ingredients are used in process (environment friendly)

During and after the process; no soil, water or air pollution is observed.

Creates economically valuable products out of wastage tyres (These are an industrial product that have a good market value and demand)

The most cost-effective wastage tyre recycling technology in the world.

Raw material (wastage tyre) is cheap and easy to provide. These are the by-products of tyre production.

Each recycled ton of tyres preserves 10 tons of CO2 that is a major green house gas.

The process can be applied to all rubber based materials.

The system creates an alternate source of energy to replace petroleum products and natural gas.

System gives the opportunity to governments and local administrations to deal with the wastage tyre problem to a great extent.

The process of Pyrolysis has duration of 4 to 12 hours, depending on the quantity and size of tyre (car tyre, truck tyre, etc.). During the process different vacuum values are applied in pre-determined temperatures and in different phases. Different gases are obtained and the condensed gas is stored as a fuel-oil in tanks.

The Perfect Solution (Pyrolysis Process):

Pyrolysis is the decomposition of organic compounds under oxygen free (anaerobic) atmosphere that produces gas, oil, carbon black and steel. Efficient industrial Pyrolysis is a process to treat the rubber and industrial plastic wastage as well.

As a result of pyrolysis of wastage tyres one obtains,

Fuel Oil (45% to 50%)

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 45% to 50% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

Carbon Black (30% to 35%)

Carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% (depending on the type of tyres) of the total amount of scrap tyres recycled in the system. Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials.

Other Information

Pay Mode Terms: L/C (Letter of Credit), D/P (Documents Against Payment), T/T (Bank Transfer)

Minimum Order Quantity: 1 Set

Port of Dispatch: Nahva seva port mumbai

Production Capacity: 10 Ton and 5 ton per days

Delivery Time: 45 days

Packaging Details: Usually It is sent in wood packing, shrink packaging sent in Containers. It has all the pipes, valves and spares necessary for the plant operation. It will be delivered upto your site in the Loree. Complete care is taken in packaging to be completely damage free. It has two 40 feet containers. It is sent via shipment through sea.

We, Anjali Exim, established in the year 2004, and have evolved as one of the major processors and Manufacture and suppliers of Waste Tyre Recycling Plants, AAC Blocks Manufacturing Line, AAC Blocks Making Machine, Pyrolysis Plant, Waste Tyre Pyrolysis Plant, AAC Blocks Plant, AAC Blocks Production Line, Waste Tyre Pyrolysis, AAC Blocks Line.

More details:View company website

Its Free

Verify Now