Additional Details

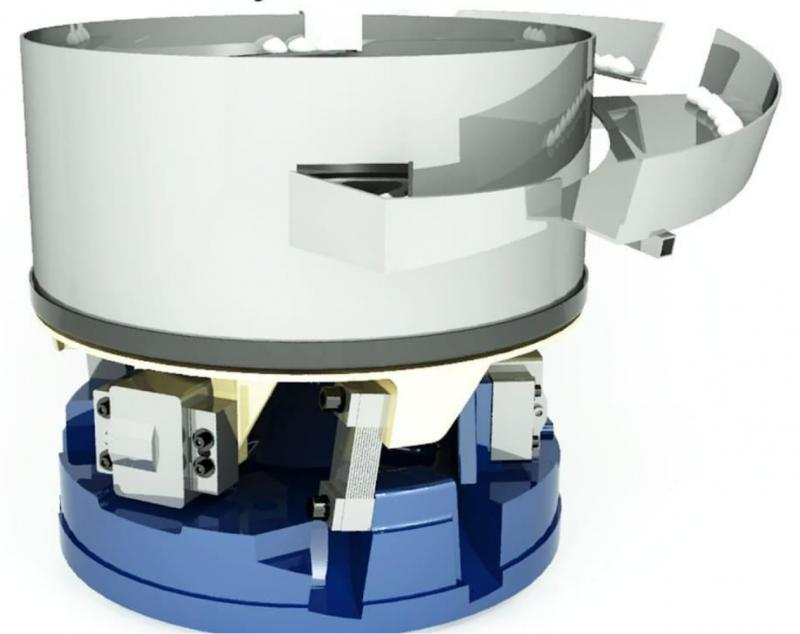

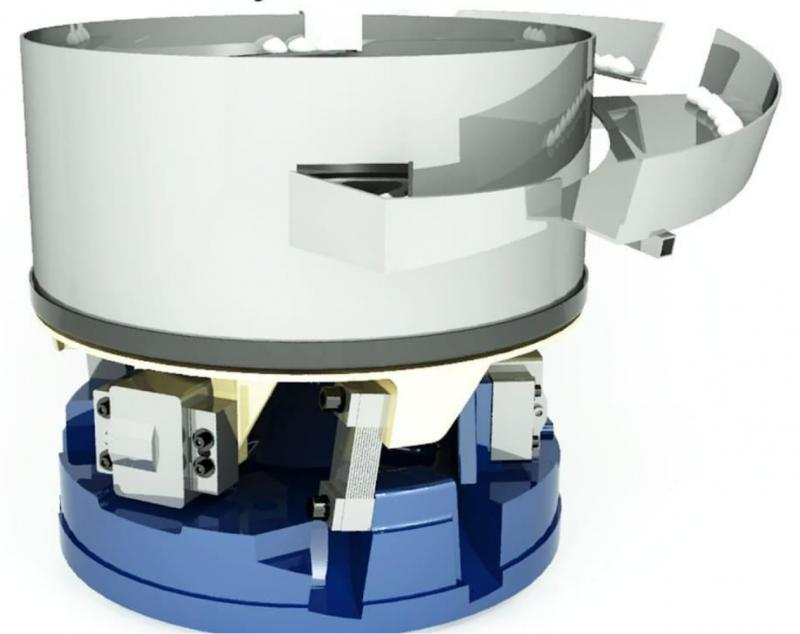

A vibratory bowl feeder is an automated system that uses vibration to sort, orient, and feed small parts in assembly lines. It consists of a specially designed bowl with ramps and tracks, mounted on a vibrating drive unit. The vibration causes parts to move up the bowl's inclined track, aligning them in a consistent orientation for further processing. This system enhances production efficiency by providing a continuous and reliable supply of correctly oriented parts.

These feeders are widely used in industries such as automotive, electronics, pharmaceuticals, and packaging, ensuring precise handling of components like screws, caps, fasteners, and tablets. They offer high-speed operation, low maintenance, and customizable designs to suit various part sizes and shapes. Advanced models include noise reduction coatings, adjustable feed rates, and integration with robotic automation systems, making them essential for modern manufacturing and assembly lines.

Technical Specifications

- Bowl Diameter: Customizable as per application requirements

- Material: Stainless Steel

- Drive Unit: Electromagnetic or Pneumatic

- Control System: Variable amplitude control for adjustable feed rate

- Coating: Optional Polyurethane/Flocking for noise reduction & part protection

- Feeding Speed: High-speed, adjustable as per part size and weight

- Power Supply: 220V/50Hz or 110V/60Hz (customizable)

- Load Capacity: Varies based on model and application

- Orientation Capability: Capable of handling small, lightweight, and complex-shaped parts

- Integration: Compatible with conveyors, robots, and automated systems

- Noise Level: Low noise operation with optional soundproofing features

- Customization: Available based on industry-specific requirements

Applications

- Automotive: Feeding components like screws, bolts, and clips for assembly.

- Electronics: Orienting small electronic parts such as connectors and pins.

- Pharmaceuticals: Handling capsules, tablets, and other medical components.

- Packaging: Aligning items like bottle caps and lids for packaging processes.

_208366.jpg)

_208366.jpg)