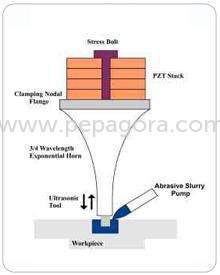

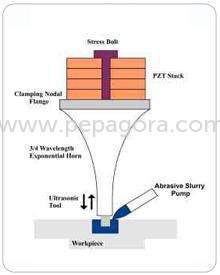

Ultrasonic milling is a relative new process that allows efficient machining of so-called advanced materials such as hardened steels, carbides, glasses and ceramics. With the aid of an ultrasonic spindle, the vibration of the machine is transferred to a diamond tool,The tool vibrates at a rate of 20, ooo times per secondm and thuse removes minuscule particles from the surface of the work piece. The simultaneous circular motion of the tool removes these particles from the working zone. In addition, the continuous separation between tool and work piece, in conjuction with the reduced feed power and lower thermal stress in comparison to conventional methods, leads to aprotection of tool and work piece, Machining is corried out much like conventional milling. Ultrasonic milling makes it possinle to machine finished parts in very hard materials at a considerably faster rate than other mehods such as dimon cutting tools or gringing. 2 to 50 microns vibrations are give which acn be adjusted electronically. Machining is done with minimized mechanical & thermal damage.

M/S Johnson Plastosonic (P) Ltd started originally as name of M/s National Indosonic.The company started it’s operations by providing services in field of ultrasonic plastic welding machines.

More details:View company website

Its Free

Verify Now