We are instrumental in offering a wide array of Toilet Soap Finishing Plant to our valued patrons. These plants are set up using high grade raw materials that are procured from the most trusted vendors of the industry. These plants are manufactured in compliance with the industry standards and norms by our proficient experts. Moreover, the entire range of products offered by us can also be availed in various customization options.

Other details:

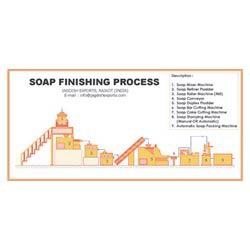

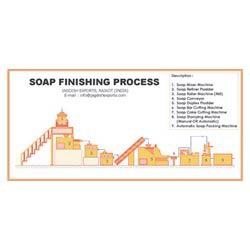

This process is started from soap mixer machine where desired color, perfume preservatives, additives and others are added

The mixed soap is then fed in to the soap roller machine where it get homogenized, finishing and final output soap in form of thin ribbon

The same thin ribbon is fed in to the duplex plodder machine which used for highest compression, finishing of soap and which produced final output of soap in bar form Automatic soap bar cutting machine is kept next to duplex plodder outlet and which cut soap in bar form

The next process is cutting of soap bar in to cake (table) which will be with suitable size of soap stamping process

Then the soap stamping machine (automatic soap stamping machine in big capacity) is used to stamp final soap in tablet (cake) form

The stamping dies of stamping machine are made specially according to buyer's selected logo, design, brand name so buyer will get final soap with desired logo, design and brand name

Features:

Soap mixing

Soap rolling

Soap double extrusion (plodding)

Soap cutting soap stamping.

Established in 1967, at Batala, Punjab, India, 'Jagdeep Foundry,' are an ISO 9001:2008 certified company engaged in manufacturing and exporting a wide range of industrial process machinery.

More details:View company website

Its Free

Verify Now