| Maximum size | : | 3000 mm X 6000 mm | |

| or | : | 3500 mm X 5000 mm | |

| Minimum size | : | 220 mm diagonals | |

| Thickness range | : | 3 mm to 19 mm | |

| Colors | : | Clear, Bronze, Gray, Green, Blue, Reflective & Low-E | |

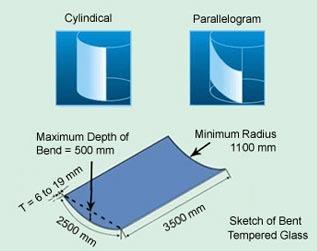

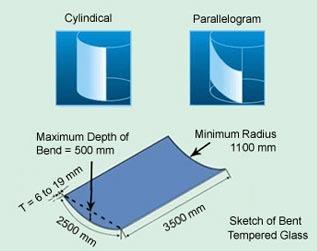

| Bent Tempered | : | 2500 mm (width) X 3500 mm (straight edge) | |

| Minimum radius | : | 1100 mm | |

Trutuf tempered glass is made on state-of-the-art, electrically heated horizontal furnaces, which heat the glass to an uniform temperature of approximately 700ºC. Ceramic rolls convey the glass through the furnace at speeds regulated to ensure temperature uniformity and minimal optical distortions. When the glass exits from the furnace, It is rapidly cooled by a series of air nozzles. This rapid cooling puts the glass surface into a state of compression, with the center core in tension. In the final Stress Distribution, the sum of the forces in compression equals the forces in tension.

Tempered glass gains its added strength from these compressed surfaces. However, if the surface is penetrated by a scratch or an impact, the glass will break into a number of small particles. The heat treatment process for toughening glass requires that all fabrication be completed prior to toughening. Any attempt to cut, drill, grind or sand blast the glass after toughening may result in glass breakage. The surface hardness is not changed by the heat treatment process. The glass surface after heat treatment will have the same resistance to surface damage as annealed glass. Tempering process does not change in any way the light transmission and solar radiant heat properties of glass.

|

|

Supplier of glasses such as plain glass, coloured glass, printed glass, reflector glass, curved glass, bend glass, annealed glass, toughened glass, laminated glass, lacquard glass, printed glasses and framless toughened glass doors.

More details:View company website

Its Free

Verify Now