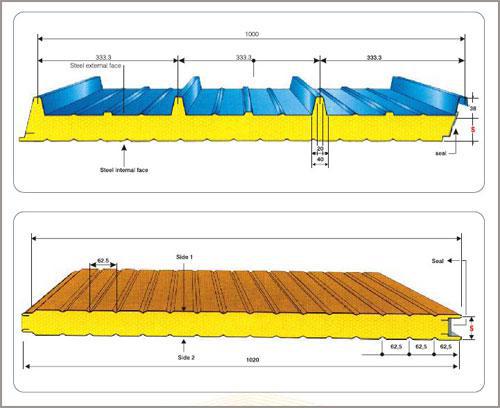

We are engaged in manufacturing reliable sandwich panels in variegated specifications. The structures are available in profile, pre-painted, zinc coated, Galvalume Coated Steel and Stainless Steel Sheets. Moreover, we use Polyethane, EPS and Acoustic core material for insulating these structures. The modular structures are cut-to-length using sophisticated machines and are supplied ready-to-install. These structures are highly durable, portable, leak proof, weather resistant and faster to erect. Available in different colors and materials, we can also customize these structures to suit specific requirements of our clients.

The Alfaa EPS Panel is a stressed skin sandwich panel, comprised of pre-painted steel skins continuously laminated over a fire retardant treated Expanded Polystyrene (EPS) core. EPS core, whilst having a fire retardant additive is not fire rated. Alfaa EPS Panel can be used in horizontal or vertical applications and with a range of colour, joint and profile options, it can meet the functional and aesthetic requirements demanded by a variety of facilities such as Sports Centres, Commercial premises, Offices, Warehouse and Factories.

Alfaa EPS Panel's range of colours, joints and profiles deliver a first class finish inside and out. The panels can be joined with a standard slip joint or a tongue and groove type joint. It allows for easy and rapid installation whilst providing greater strength in walls and a clean, smooth aesthetic look.

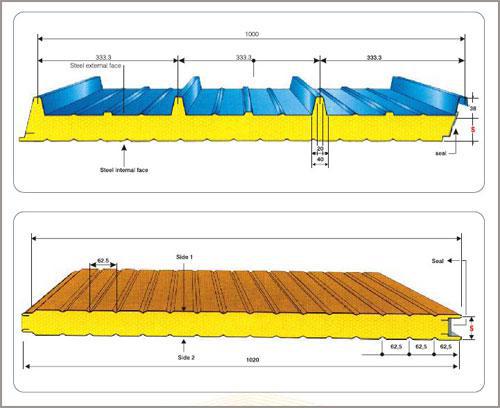

Rock wool sandwich panel adopts fibrous rock wool as the core material, and color steel plate as its surface layers. The rock wool and two color steel plates are pressed together through the automation of a forming machine and then glued together by a high strength adhesive. Since the color steel plate and the rock wool are noncombustible, the rock wool sandwich panel has an excellent fireproof property. Our rock wool sandwich panels include roof panels and wall panels. Since they are fireproof, heat insulated and sound insulated, they are widely used to construct roofs and walls of industrial buildings and civil buildings. They are especially suitable for use in buildings that require a high degree of being fireproof.

Features:

1. High rigidity: the rock wool and pair of steel plates are glued together, making its aggregate rigidity superior to that of the composite board. Moreover, after the sandwich panel is fixed by connectors and purline, its integral rigidity is improved.

2. Reasonable fastening method: the rock wool roof panel adopts a buckle fastening design to avoid water leakage in the seam. This eliminates the need to use additional accessories.

3. Reliable fixing method: the rock wool roof panel is fixed by a special self tapping screw and purline, which can effectively resist typhoons and other external forces.

4. Short installation period: there is no need for on-site installation or processing of the rock wool sandwich panel.

5. Scratch proof: in the production of rock wool sandwich panels, a layer of polythene adhesive film can be glued to the surface of to avoid scratches during installation or transportation.

Furthermore, our rock wool sandwich panel has excellent fireproof, sound absorbing, heat insulating, and sound insulating properties.

Engaged in supplying aluminum ceiling panels, aluminum wall panels, aluminum metal sheet, perforated aluminum sheet, aluminum insulated panel and aluminum roofing sheets.

More details:View company website

Its Free

Verify Now