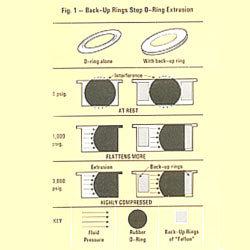

Addition of one or two back-up rings of PTFE resin will greatly augment the life, performance and reliability of O-ring seals. With proper mechanical design and materials of construction, O-rings generally serve as effective seals for reciprocating or rotating shafts, over wide ranges of temperature and pressure; they also offer the advantages of sealing in both directions. One big drawback of O-rings, however, is their tendency to extrude under pressure into seal clearances (see Fig. I). Degree of extrusion depends on hardness of the O-ring, clearance between parts, and fluid pressures involved. Use of back-up rings of PTFE - fluorocarbon resins will stop O-ring extrusion. Such rings are much harder than rubber O rings, yet they deform enough to block-off clearance to the O-ring.Fig. 2 shows a rule-of-thumb chart that is useful as a guide to indicate whether anti-extrusion rings should be used with static and dynamic O-rings of rubber.The following advantages relate to back-up rings of PTFE as anti-extrusion devices: Compared with leather, the previous standard material, back-up rings of PTFE are easier to make or buy to the close tolerances required in a precision sealing installation. Back-up rings of PTFE are compatible with all hydraulic fluids. They are essentially chemically inert, and do not embrittle or fibrilate. <liInstallation is easier; rings of PTFE are usually spiral or scarf-cut, and can be slipped over a shaft: there's no right and wrong side; and they require no oil soaking or drying out prior to installation. PTFE back up rings retain their outstanding properties at high temperatures (500° F.) Some reinforced rings are in use at even higher temperatures. The exceptionally low coefficient of friction of PTFE lower than that for any other solid material-cuts break-away friction to a minimum. The resins deposit a molecular coating on all surfaces contacted; this imparts low friction to mating surfaces. And, back-up rings of PTFE can be installed at a cost saving over back-up rings of leather. When Extrusion is Not a Problem -Back-up rings of PTFE can greatly improve O-ring seal installations even if extrusion does not present a problem.Longer O-Ring Life - For instance, the majority of O-ring failures occur either by nibbling or spiral failure. The Zero clearances provided by PTFE back-up rings reduce tendency toward nibbling; and spiral failure is prevented because the molecular coating that PTFE resins deposit on the cylinder surface permits the rubber O-ring to slide evenly without slipping or rolling. This molecular layer also lowers break-away friction of rubber O-rings.Savings is Machining - The standard recommended 32 rms. surface finish on ring grooves is an expensive machining operation. When using back-up rings of PTFE, this requirement is not as critical, and the groove may be left in the as-machined condition, normally 64-120 rms. Savings in maching alone often pay for the small cost of back-up rings of PTFE resin.

Engage in manufactured and supply of moulded and precision machinery products from pure and filled PTFE.

More details:View company website

Its Free

Verify Now