Main two types of systems:

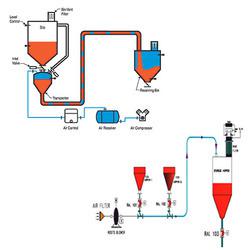

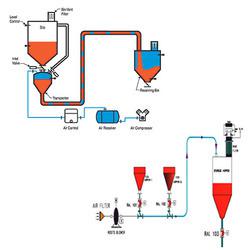

Pressure type conveying system, in which material is conveyed with the help of air pressure upto destination

Suction type conveying system in which material is sucked from source & discharged by gravity upto destination

Types can be sub-categorized as:

Lean phase conveying system

Semi-desnse phase conveying system

Dense phase conveying system

Salient features of lean phase conveying system:

Use low pressure, high volume gas & high velocity for fluidizing to transfer powder or granular bulk solids up to capacity 50tph

Solid to air ratio ( kg solid / kg air) less than 15

Systems use a positive displacement blower (required press. <1bar) to develop the required motive force

Rotary valve & venture can be used as feeder in lean phase conveying system

Lean phase systems are most used on those material which are non-abrasive, non-fragile, light density (typical <800kg/m3)

Dense phase system:-dense phase pressure system utilizes high pressure, low volume (cfm) air / gas as the motive force to transfer powder or granular bulk solid through a pipeline at low velocity

Salient features of dense phase conveying system:

Use high pressure, low volume gas & low velocity for fluidizing to transfer powder or granular bulk solids

Pressure vessel with valves & air control is the key components of the system

Solid to air ratio ( kg solid / kg air) should be more than 15

For dense phase pressure system conveying length is up to 400mt. Approx

This systems use compressed air / gas to develop the required motive force

Specially designed pressure vessel is used as feeder in lean phase conveying system

Dense phase systems are most used on those material which are abrasive, fragile, high density.

We, Mechatronics Solutions Private Limited (MSPL), are an emerging company in the sector of engineering & allied industries, which provides a wide range of material handling systems equipments, solving the needs & requirements of these industries.

More details:View company website

Its Free

Verify Now