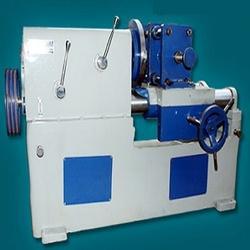

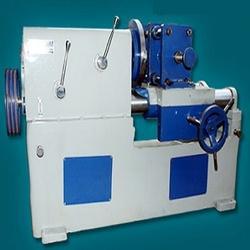

We deal in Pipe End Facing ( Chamferimg) Machine of best quality to our clients.

General:

The Machine is used for the purpose of Chamfering and De burring of the Pipe before Galvanizing and Threading Operation. Pipe is chamfered from the Outer and Front face by two different tools. The Pipe remains Stationery and the Facing Head rotates. Slide Travels towards Facing Head for Chamfering manually.

The Machine mainly consists of the following:

Base

Head Stock

Saddle

Clamping Vice

Base:

The Base is made of Cast Iron. It is Very Rigid and sturdy in construction so as to take maximum Load and absorb max. Vibrations. It is provided with four Nos. Foundation Holes of Dia M20 at four corners of the bed. The Head Stock and Clamping Vice is fitted on the Bed.

Head Stock:

The Head Stock body is made of Cast Iron. It is Very rigid and sturdy in design. The Head Stock is designed for Two Nos. Spindle speeds(or Four speed can be Supplied). All the Gears are of Helical type made out of Axle Forging. The width of gears is 50 mm (for Four speed ). The Shifting Gears slide on Splinted Shafts. The Shafts are mounted on Heavy Duty Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts. The Main Spindle is mounted on two Taper Roller Bearings. The Head Stock is Oil Filled. It is provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator.

Two Pillars are fitted in the Head Stock body precisely aligned with the main Spindle Axis and supported on other end. The Pillars are Hard Chrome Plated Ground and finished to minimize the wear and tear. A special Facing Head will be provided with the machine fitted on the Main Spindle. Two Tools of HSS will be used, for outer and front Chamfering.

Saddle:

The saddle is moved on the Pillars (Hardcrome Plated). Two Half Bushes are fitted on the saddle below the pillars, adjusted in such a way that there is no extra clearance in the Saddle and Pillars. It is provided with rack and pinion arrangement to move the Saddle. Lubrication Points are provided wherever necessary.

Clamping Vice:

The Pillar Type Clamping Vice made of MS rods (Hardcrome plated) and plates fitted on the Saddle. The Vice is provided with Finger Type Clamping Jaws for for 4” to 12” size Clamping the Entire range of pipe size in its cap. The Pipe Clamping Jaws are fitted on two sliding blocks precisely machined, fitted in the pillar Type Vice. Movement of the sliding Blocks is made by means of a Nut & Screw arrangement, which is then fitted with a Heavy duty Handle. One Block remains Stationery while the second moves for the clamping purpose.

| Min. Dia of Pipe to be Chamfered | 4”or 6” N.B. Pipe |

| Max. Dia of Pipe to be Chamfered | 12” |

| Cutting Tools Required (HSS 10% Cobalt) | 5/8”0r 3/4” |

| Number of Spindle Speeds | Two or (Four.at extra cost) |

| Range of Spindle Speeds | 51 to 128 RPM |

| Main Motor Required | 7½” H.P., 960 RPM. |

| Approx. Wt. Of the Machine. | 3500 Kgs.To 4000 kg |

Established in the Year 1983 and backed by in-depth industry experience, we have been able to create a bench mark in the industry through Supplying, Manufacturing, Exporting a wide range of tool industry machines. Our range of machines comprises of Pipe Treading Machine, Beveling Machine, Pipe Beveling Machine.

More details:View company website

Its Free

Verify Now