This is achieved by, a valve. Sometime the pressure reduction is done in multiple stages through a series of pressure reducing valves.

Due to throttling the pressure from high pressure to low pressure, shock and turbulent wave emanated across the valve orifice releases a very high amount of acoustic energy which is transmitted as fluid borne acoustic energy in the downstream pipeline

This would result in very high vibration in the pipeline and may also lead to structural damage due to mechanical noise transmission through structures.

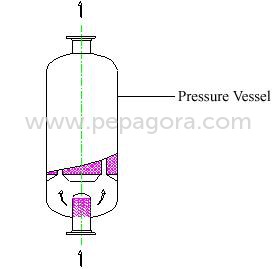

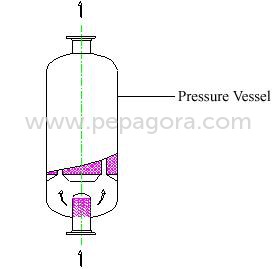

This can be solved by connecting an absorptive type silencer with properly designed diffusing arrangement and an expansive chamber immediately after the valve. When series of throttling valves are used for multiple stage pressure reduction it is advisable to fit a silencer for each stage. Alternatively, the throttle valves can be installed close to each other and the silencer can be installed in the last stage. However this arrangement requires proper acoustic treatment of all the valves and interconnecting pipe work.

The silencer vessel is normally designed as a pressure vessel as per

ASME SEC VIII DIV I or as per customer requirement.

Acoustics India is an established player in the field of industrial noise control with over two decades of experience in the field. We have over 3000 installations in a variety of industries which include steel, power, engineering, fertilizers, oil and chemical industries.

More details:View company website

Its Free

Verify Now