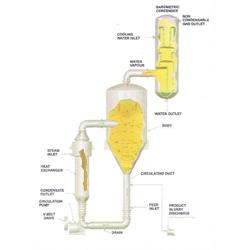

Evaporators are ideally suitable for concentrating a range of solutions consisting of non volatilesolutes( i.e. Solids) and volatile solvents(i.e. Water or any other solvents) Evporator mainly consists of the following equipments: Calendria , vapor separator, vacuum pump,condensate pump, feed pump, transfer pump etc.

How it works:

In this approach two or more evaporators are arranged in series such that, vapours generated from preceding effect will act as a heating media for the next effect i.e. water vapour generated in the first effect vapour body will be used as a heating media for the second effect and so on for evaporation in further effect.

The reduction in the steam consumption is proportional to the number of effects i.e. two effects reduces steam consumption to about ½, three effect to about 1/3 and four effect to about ¼.

ENERGY SAVINGS: Energy saving is primary consideration in the design of each and every evaporator. In evaporator heatingmedia used is thermal energy i.e. steam, so energy saving can be specified in terms of reduction insteam consumption per kg of evaporation. Type OF Evaporators : Multiple Effect Evaporators, Falling Film Type, Forced Circulation Type, RisingFilm Type, Combination Evaporators.

Pharmaceutical

Fine chemicals

Food & beverages

Offering services which includes engineering consulting, detailed engineering service, procurement support detailed engineering service and plant layout design detailed engineering service.

More details:View company website

Its Free

Verify Now