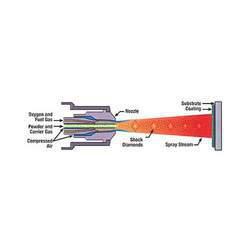

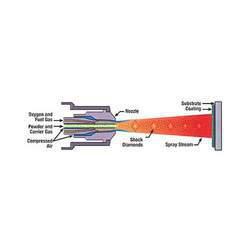

We are one of the leading service providers of HVOF (High Velocity Oxygen Fuel) which is basically same as that Combustion Powder Spray Process (LVOF). This process has been developed to produce high spray velocity as these coatings are very dense, strong and have low residual tensile stress. There are plenty of HVOF guns which incorporate various methods to gain high velocity spraying. One of the method is through high pressure water cooled HVOF combustion chamber and a nozzle. In this method fuel and oxygen are fed into the chamber and high pressure of flame is forced down the nozzle increasing its velocity.

The other method includes a simpler system of a high pressure combustion nozzle and air cap. This method is followed by supplying fuel gas and oxygen at high pressure and thus the compress air occurs outside the nozzle but within the air cap. This compressed air accelerates the flame and acts as a coolant for the HVOF gun; finally the powder is fed under high pressure directed from the centre of the nozzle.

Specifications:

1.Coating Material Form: Powder

2.Heat Source: Oxy-Fuel Combustion

3.Flame Temperature (in 0C): 1500 +

4.Gas Velocity (m/sec): 1500 +

5.Porosity: 1 to 5 %

6.Coating Adhesion (MPA): 70 +.

Associated Plasmatron Private Limited, was established in 1988, with the aim of providing state of the art Thermal Spraying services to the industry.All through these years, the Company has proven its competence and today is a front runner in the Surface Engineering industry .

More details:View company website

Its Free

Verify Now