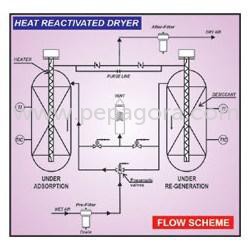

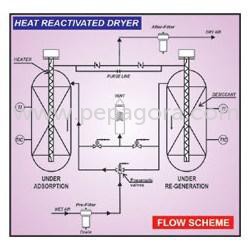

Due to dry air purge and thermal regeneration, residual moisture loading on desiccant becomes low and this gives low dew points. The drying unit has 2- vessels filled with activated alumina desiccant. One vessel remains in drying cycle for 4-hours while other vessel is simultaneously regenerated at atmospheric pressure. Around 3 to 5% flow of air dryer capacity is used as purge for regeneration. Electrical heaters are provided in a central finned stainless pipe in drying vessels. Heating cycle is for 2-hours and in this time desiccant temperature increase up to 100 to 150 degree Celsius. at this temperature regeneration is complete. Dew point achieved is around and above (-) 60 degree Celsius. These dryers are some more costly than heat less type but are more suitable for Dew points lower than -60 degree Celsius to -80 degree Celsius and purge loss is also less than the Heat less type i.e. around 3 %.

Incepted in the year 2003, it is one of the prominent organizations engaged in manufacturing, supplying and exporting of industrial plants and equipment like industrial filters, industrial heat exchangers, ammonia cracking units, exo gas generators, gas exchangers, gas generators, compressed air / gas drying system, pressure vessels and others.

More details:View company website

Its Free

Verify Now