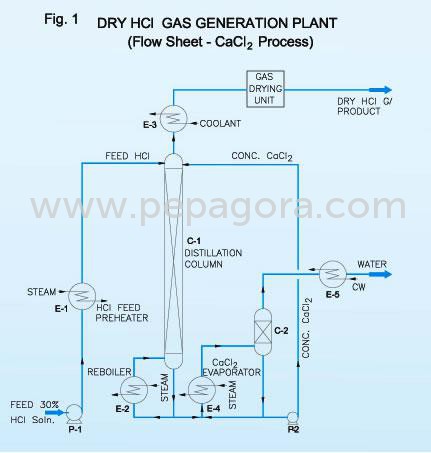

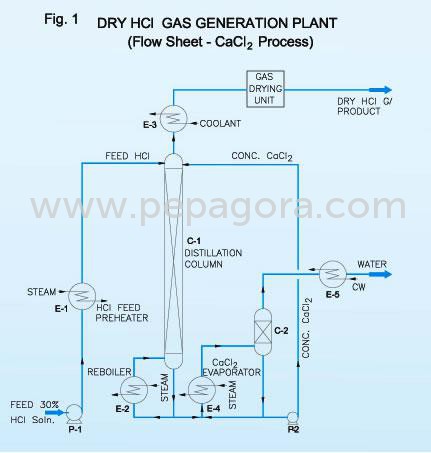

The plant has been designed to produce HCl gas by the process of distillation of 30% hydrochloric acid solution. The plant has been designed to operate as a continuous process. The feed 30% hydrochloric acid solution is pre-heated by the outgoing hot bottom product in the heat exchanger (E-3) and fed to the azeotropic distillation column by the pump. The feed rate is controlled. The heat exchanger (E-1) is designed as a thermosyphon reboiler where the heat energy is supplied by steam. The vapour from the reboiler strips the available gas from the feed acid soln. in the column. The bottom product from the plant is constant boiling 20% acid soln. which is cooled in (E-3) by the cold 30% acid feed solution prior to discharge. The top product HCl gas is dried in the Drying Unit using a suitable dehydrating agent. The moisture content in the product HCl gas is expected to be less than 0.001%. Once all the operating conditions are stabilized and maintained; rate of generation of HCl gas depends only upon rate of hydrochloric acid (30%) feed. All the wetted parts of the system are fabricated from corrosion resistant materials (Glass and PTFE).

Engaged in exporting and supplying a wide range of cooling systems such as heat exchanger cooling systems, evaporation equipment, evaporation cooling equipment and industrial evaporation equipment.

More details:View company website

Its Free

Verify Now