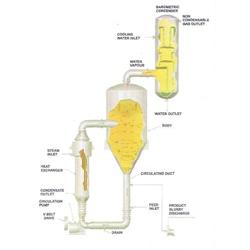

Our range is used when the boiling of feed liquid on the heating surfaces is to be avoided due to the fouling and salting characteristics of the liquid. Known as short tube evaporators, the flow velocity in the tubes of these products is kept very high.

How it works :

Slurry is pumped from the bottom cones through the tubes of vertical heat exchanger, here in this evaporator tubes are filled with liquid. Steam condenses outside the tubes and provides the heat required for the evaporation. Sufficient hydrostatic is maintained above the top tubesheet of exchanger before liquor enters into the vapour separator, to suppress the boiling of liquid on tube surfaces. Since forced circulation leads to high tube side velocities and hence higher heat transfer coefficients and smaller heating surfaces required. Also because of high velocities of liquid in tubes fouling can be controlled well.

Advantages:

Highest operational flexibility

Ideal for crystallizing solutions

For concentration of thermally degradable materials and viscous solutions

Higher turndown ratio

Sodium sulphate, Sodium Chloride & Other crystalline solutions

Effluent volume reduction.

For recovering pure condensed water from the evaporation of wash/waste water.

Offering services which includes engineering consulting, detailed engineering service, procurement support detailed engineering service and plant layout design detailed engineering service.

More details:View company website

Its Free

Verify Now