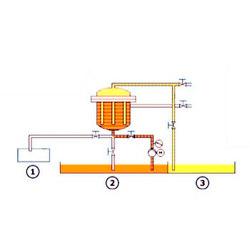

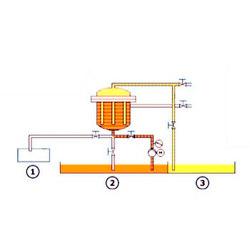

Dai Chi Fine Filtration Systems offered by us is based on edge filtration technology and effectively utilize stack of paper discs that are tightly compressed on tubular cores so as to form continuous cylindrical surface where contaminants are filtered at edge of Filter Candles. These are offered for different methods of operations including Sludge box, Fouled tank section and clean tank section.

Stages of Operation (Fine Filtration System):

Step 1 :

Filtering mode in normal operation

Dirty oil from grinding machine is taken from Dai Chi dirty oil storage area & introduced into filter vessel

Oil is forced to centre of each element

All particles larger than one micron are trapped on O.D. of filter element

Clean oil is deposited into DaiChi's clean oil storage area & delivered to Grinding machine upon demand

Step 2 :

Draining mode prior to back flushing elements

Filter vessel is drained into dirty storage area through use of compressed air

Step 3 :

Back flushing mode is fully automated

Compressed air is introduced through top & center of each element

Dirt & debris are forced out of filter vessel into paper lined sludge box that should be emptied approximately once a month

Entire back flushing procedure takes only six minutes

Advantages :

Filtration down to 3 um below

Automatic operation without the use of consumables

Low maintenance costs

Extended coolant life

Increases surface finish of product

Decreases production cycle time

Reduce operating costs

Comparative Chart :

1 Micron = 0.001 mm

40 microns = White blood cell

70 microns = Human hair

100 microns = Table salt

Manufacturer of industrial cooling systems like panel air conditioner, electronic air conditioner, commercial air conditioner, water chiller, coolant chiller, process chiller, hydraulic process chiller and oil chiller.

More details:View company website

Its Free

Verify Now