Our clients can avail from us an extensive range of Falling Film Evaporators, which is manufactured with the use of finest grade raw material and latest technology. These products are the special heat exchangers that are useful in assortment of various industrial applications. Furthermore, our clients can avail these products in varied specifications to suit their exact requirement. These products are suitable for solutions with viscous liquids, high temperature sensitivity, concentration of herbal extract solutions with recovery of solvents like methanol, chloroform and hexane.

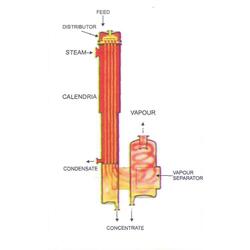

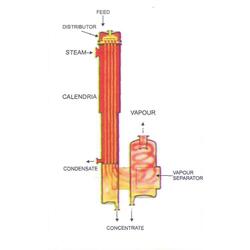

How It Works:

In Falling Film Evaporators, The feed liquor is introduced at the top tubesheet, and flows down the tube wall as a thin film. Since the film is moving in the direction of gravity rather than against it, a thinner and faster moving film results, yielding higher heat transfer co-efficient and reduce contact time. Mixture of vapour and liquid comes down and vapour liquid separation takes place at the bottom.

Advantages:

Higher Heat transfer co-efficient.

Satisfactory Operation at low temperature driving force.

Handling of heat sensitive and viscous chemical products.

Suitable for foaming or frothing liquors

Fertilizer Industry- Urea, Ammonium Nitrate

For Food & Dairy Products

Herbal Extracts

Offering services which includes engineering consulting, detailed engineering service, procurement support detailed engineering service and plant layout design detailed engineering service.

More details:View company website

Its Free

Verify Now