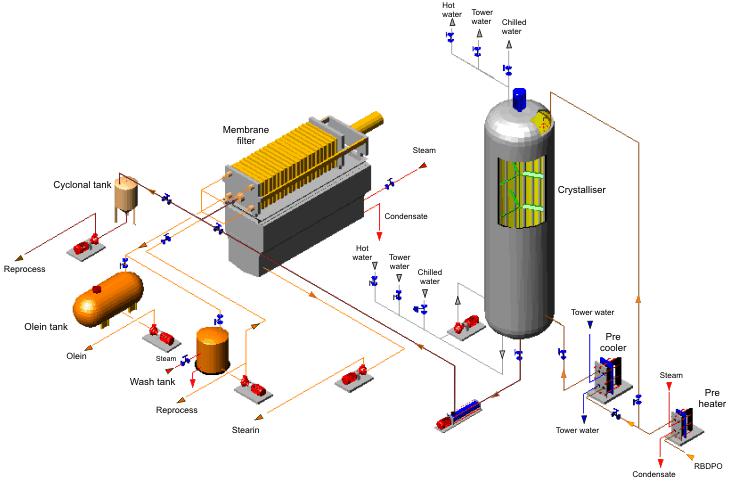

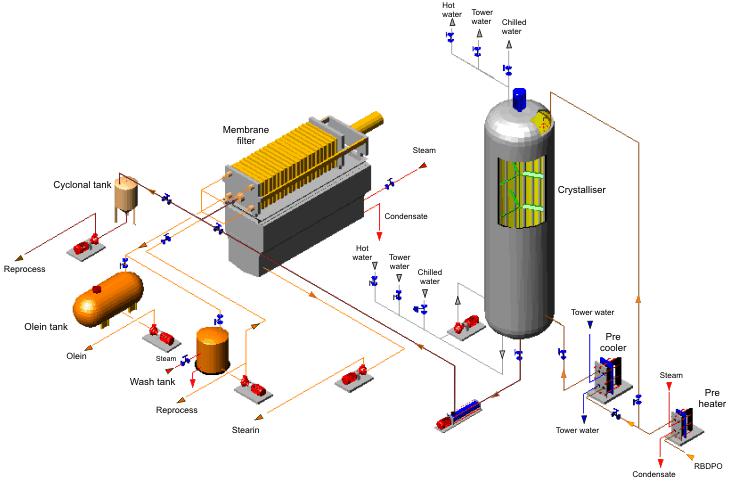

We offer dry splitting facilities to our customers. The dry fractionation system is designed to process crude palm, ore-treated or RBD. This makes the process simpler without any hazardous waste for the product environment.

The process consists of 5 steps:

(1) Heating of feed oil

(2) Crystal Formation by Controlled Cooling

(3) Crystal growth

(4) Crystal Maturation

(5) Filtration to separate olein and stearin

The filtration is carried out by the vacuum created by the vacuum pump and the filtrate is collected in a receiver equipped with a moisture trap. The vacuum is generated by the vacuum pump with water ring. The suction force creates a continuous and constant suction head under the submerged part at 20 ° C to 25 ° C of sludge. The vacuum sucks the olein into the receiver. The stearin forms a uniform layer on the filter cloth attached to the rotating drum. When the drum rotates, the progressive drying takes place at the end of the revolution. The cake is blown again with air and using the scrapper blade, the stearin is discharged into the collection tank, which is provided with a steam heating device for flux melt, Then transported to the storage tank by the pump. The olein in the form of filtrate is collected in the receiver and then transported into the storage tank.

Incepted in the year 1990, Glamptech Agro Process Pvt. Ltd. has emerged as one of the foremost service provider and designer in the field of Continuous Solvent Extraction / Vegetable Oil Refining, process equipment, dewaxing plant and allied industries.

More details:View company website

Its Free

Verify Now