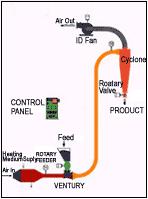

Operating Principle

Feed wet cake is dispersed in the mechanical dis integrator and is entrained in the stream of hot air coming from hot air generator. Almost immediate drying takes place due to very large surface area exposed to the hot air.The air conveys the material through the drying duct where remaining moisture is removed. The air and the dry solids are separated and the dry solids are discharged continuously via the rotary valve. The humid air is exhausted out via a dust separator.

Special Features of Continuous Particulate Dryer

- Suitable for handling wet feeds in the form of wet powder / wet cake/ paste having primarily surface moisture.

- Very uniform drying of all solids due to excellent dispersion in the stream of the drying air.

- The product is typically in uniform powder form.

- Due to exceedingly short drying time heat sensitive materials can be handled.

- High thermal efficiency

- Continuous operation

- Compact installation

» Boric Acid

» Calcium Carbonate (PCC / ACC)

» CPC Blue/Green/Crude

» Di-Calcium Phosphate

» Fibre (Starch)

» Glyphosate

» H Acid, J Acid, Gamma Acid

» Metanillinic Acid

» Optical Whitening Agent

» Oxalic acid

» Potassium Persulphate » Barium Carbonate

» Citric Acid

» FC Acid

» DASDA

» Gluten

» Hydoquinone

» Inorganic Salts

» M Acid

» OCPNA / PCONA

» Polymer Beads

» Pigments

Arrowhead Seperation Engineering Private Limited are primarily engaged in design and manufacture of various process equipment with specialization in continuous drying and cooling system equipment.

More details:View company website

Its Free

Verify Now