For more than 20 years, Clear Edge has been a leader in providing cost-effective de-dusting systems for critical industrial processes.

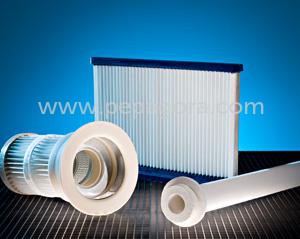

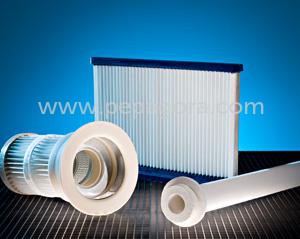

We have many years of experience designing and using Compact Filter Elements (CFEs), which have a variety of applications:

Welding fumes, especially in laser cutting in high purity environments

Automotive, including paint shop spraying

Construction and mining, including tunneling

Milling, especially power handling

Our CFEs are highly engineered, self-supporting filter units, with a proprietary technology that combines the advantages of filter bags and cartridges. Depending on the application, Clear Edge can customize the filter elements with oleo- and hydrophobic, temperature resistant, microporous coated, PTFE-membrane surface, and antistatic finishes available.

In addition, CFEs can handle high dust load environments and be cleaned efficiently by reverse pulse cleaning.

Our CFEs offer a number of valuable benefits:

Up to 3 times more filter area compared to conventional filter bags

Can reduce filter house volume by up to 70 percent

Can save up to 40 percent on running and energy costs

High efficiency

Long service life (3-5 years)

Excellent cake removal achieved with reverse pulse cleaning

Simple and quick to clean, install and replace

Can be retrofitted into existing units

CFE are more compact, making indoor installations possible

Exporter and manufacturer of edible oils, palm oils, cooking edible oil, food edible oil, aromatic edible oil, natural edible oil, essential edible oil, seeds edible oil, fresh edible oil and healthy edible oil.

More details:View company website

Its Free

Verify Now