_27620.jpg)

_27620.jpg)

_27620.jpg)

_27620.jpg)

_27620.jpg)

_27620.jpg)

_27620.jpg)

_27620.jpg)

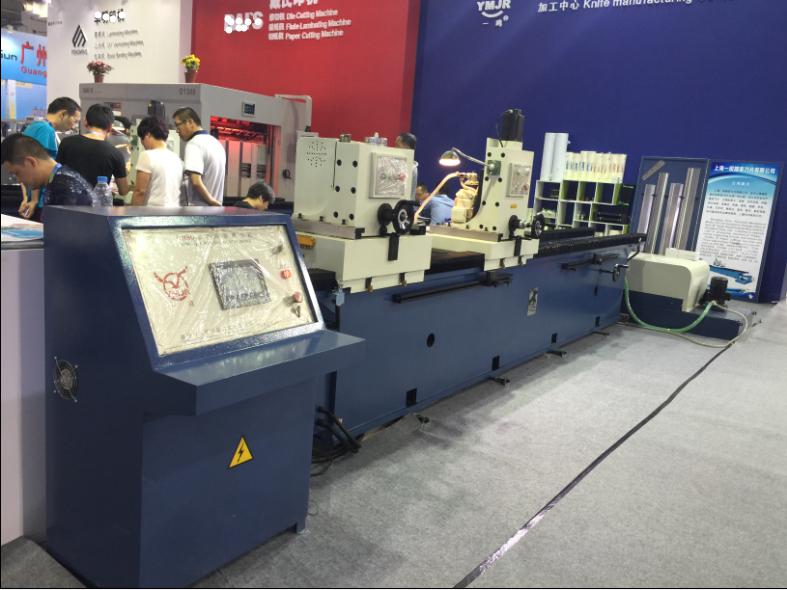

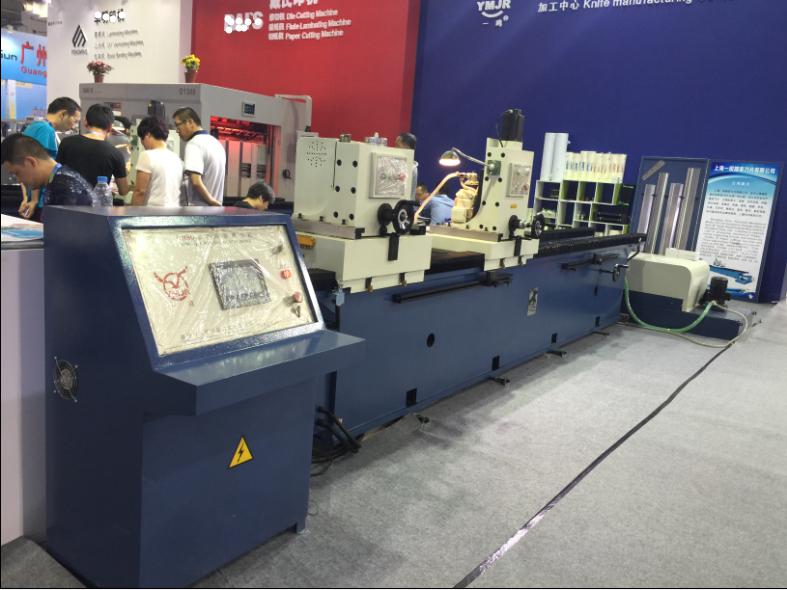

Automatic sharpening Grinder DMSQ-HF-FJ-series, gantry body, which adopts the carbon constructional quality steel;

Its equipped two grinding motors which can grind the blades in one time by different stones. The transmission is linear guide and rack and pinion system, that the machine can last longer, travel more stable drive.

Automatic feed grinding wheel by the PLC program control system, automatic control, and memory, storage and dynamic tracking, simple operation,

greatly reducing the time to prepare workpiece; can automatically adjust times of coarse grinding and accurate grinding.

The machine is the best choice for medium-sized printing warehouse, special for polar and other high-speed steel and carbide steel blade sharpening.

The multi-layer filter device consists of magnetic separator and paper filter which mechanism transmission, chain, chain network and micro-switch, etc.

The first step filter via the magnetic separator and then the purified liquid goes to the filtering paper on the conveyer belt ,

with the constant accumulation of impurities on the filtering paper andfiltration capacity decreased , the liquid level will gradually rise,

when it reach to the specified position,float ball rises and micro-switch turn on; the reducer drives the conveyer belt mesh forward

and takes the sewage & dirty paper into the sewage tank; then the liquid level drops and the micro-switch resets ;

The tank with water shortage alarm device which can measure and control the water level so as to effectively save time and improve efficiency.

Main function and Technical parameters

● water-cooled motor grinding

●purification device

● grinding head can move back and forth

● Frequency Control (stroke movement)

● automatic grinding stone feeding

● rack and pinion

● Gantry body

● magnetic chuck

● worm head drive

● table rotation angle: 0 ~ ± 90 °

● imported linear guide

● auto greaser device

● multi-layer filter device

● imported electrical components (critical control systems are imported electrical appliances)

● HMI touch screen

●Main transmission: rack and pinion transmission

● Dimension of grinding wheel: (ring shape) Ф200xФ150x100mm

● Maximum grinding width: 300 mm subject 22°

● Efficient height between grinding wheel and working table: 80 mm

● Circumrotating angle of working table: 0~±90°mm

● Rotate speed of the wheel head: 0-1800 Rpm /Min (frequency adjustable)

● Motor moving speed: 3-20 m/min (frequency adjustable)

● Power of the main electric motor: 0.75 kw

● Power of the wheel head electric motor: 4 kw

● Power of the pump electric motor: 0.75kw

|

Specifications / Model |

Maximum grinding length (mm) |

Overall dimensions (mm) |

Weight (kg) |

|

1700HF |

1700 |

4080x1000x1550 1800x1200x650(filter) |

4200 |

|

2200HF |

2200 |

4680x1000x1550 1800x1200x650(filter) |

4700 |

|

2600HF |

2600 |

5080x1000x1550 1800x1200x650(filter) |

5200 |

|

2800HF |

2800 |

5280x1000x1550 1800x1200x650(filter) |

5700 |

|

3000HF |

3000 |

5480x1000x1550 1800x1200x650(filter) |

6200 |

|

3200HF |

3200 |

5680x1000x1550 1800x1200x650(filter) |

6500 |

|

3500HF |

3500 |

5980x1000x1550 1800x1200x650(filter) |

7000 |

|

4000HF |

4000 |

6580x1000x1550 1800x1200x650(filter) |

7500 |

|

4500HF |

4500 |

7080x1000x1550 1800x1200x650(filter) |

8000 |

ISEEF ENTERPRISE INC. , is a packaging machinery manufactures group in Wenzhou, CHINA , has more than 10 different factories approved CE certificate and ISO9001,

More details:View company website

Its Free

Verify Now