Development:

Nickel Chromium composite saved by sputtering process on high alumina earthenware bars.

The film is completely stabilized to guarantee long life and unwavering quality. Fine helixing is carried out to get faultless qualities. Pivotal leads made of high conductivity Electro Tinned Copper wire are welded to the pressed end tops to guarantee unbending development. Different layers of light blue shade epoxy is covered to guarantee high protection, voltage confirmation and insurance against intense tropical natural conditions.

Characteristics:

Extremely high stability and unwavering quality

Low TCR

Low clamor level

Magnificent high recurrence qualities fits in with to MIL and JSS particulars

Endorsed by LCSO, C-DOT and most client associations

| 1. Short time overload | ±0.5% | |

| 2. Damp heat (56 days) | ± 1% | |

| 3. Load life stability 2000 hrs at 70 *C | ± 2% | |

| 4. Temperature cycling | ±0.25% | |

| 5. Resistant to solvent | No color bands going off. | |

| 6. Insulation resistance | Minimum 10,000 M.ohms | |

| 7. Resistance to soldering heat | ±0.25% | |

| 8. Dielectric strength | 2xwork. Volt. No breakdown | |

| 9. Solderability Good tinning | 95% coverage | |

| 10. Temperature limits | T 65/150 (-65*C to +150*C) | |

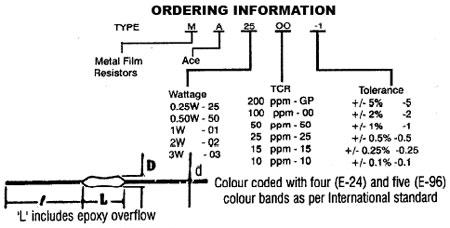

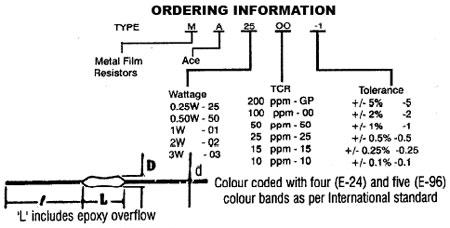

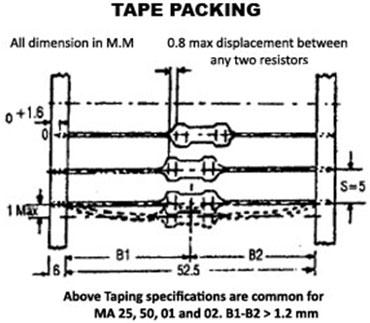

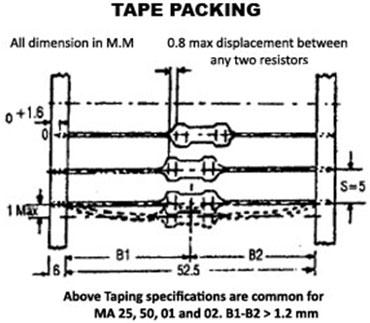

| Tape Packing/Box: | ||

| MA 25 | 2000 | 5000 |

| MA 50 | 1000 | 2500 |

| MA 01 | 500 | 1500 |

| MA 02 | 500 | 1200 |

| MA 03 | 100 | 100 |

| MA 25 also in 26mm tape 5000/box | ||

The electronics industry experienced a radical change in India since the early '80s, provoking us to enter the business around then, with contemporary engineering.

More details:View company website

Its Free

Verify Now