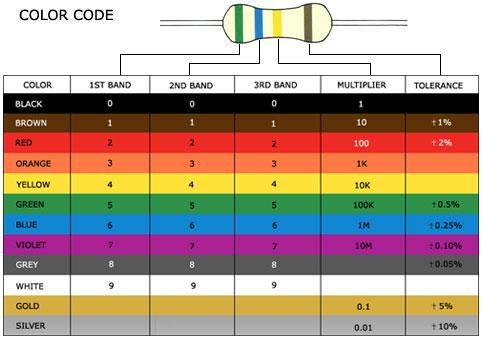

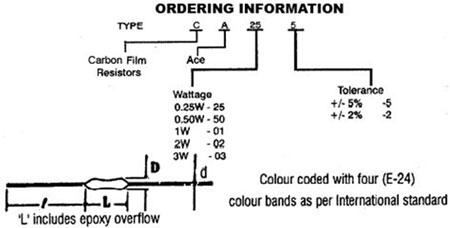

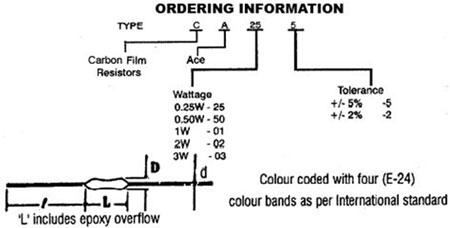

Ace high stability Carbon Film Resistors are covered with a slim film of highly immaculate carbon on high alumina ceramic poles by pyrolysis, under regulated conditions. The last ohmic worth is attained to close tolerances by consistently helixing on accuracy transported in machines utilizing low IRV, to guarantee high stability and long life. The lead wires are welded to the closure tops with Electro Tinned Copper wire, weld quality tried on the web, beat to withstand transient over-burden, covered with numerous layers of epoxy and colour coded with four colour groups (E-24 Series) to global models.

Characteristics:

High stability

Long administration life

Minor measure

Low commotion uncommon epoxy covering for security and separation against extreme tropical introduction and dampness.

| Temperature Co-efficient | ±300 ppm / °c for < 10E Upto 3M3 < -1000 ppm Above 3M3 > -1000 ppm |

| 2. Voltage Co-efficient | 50 ppm/V Max |

| 3. Moisture Resistance | ± 2% |

| 4. Load Life Stability 1000 hrs to 70°c | ± 2% |

| 5. Noise Level | Upto 100K < 0.1 µv/v Above 100K < 0.3 µv/v |

| 6. Soldering | Good tinning, 95% coverage |

| 7. Temperature Cycling | ∆ R max ± 0.5% |

| 8. Resistance to Solvent | No color bands going off. |

| 9. Short Time Overload | ∆ R max ± 0.5% |

| 10. Insulation Resistance | Min 10,000 MΩ |

| 11. Dielectric Strength | 2 x work. Volt. No breakdown ∆ R max ± 0.5% |

| Tape Packing/Box: | ||

| CA 25 | 2000 | 5000 |

| CA 50 | 1000 | 2500 |

| CA 01 | 500 | 1500 |

| CA 02 | 500 | 1200 |

| CA 03 | 100 | 100 |

| CA 25 26mm tape form is also available qty/box 5000nos | ||

The electronics industry experienced a radical change in India since the early '80s, provoking us to enter the business around then, with contemporary engineering.

More details:View company website

Its Free

Verify Now