ZEOCHEM ANTICORR

Product Range

Fact Sheet

- Location:Gujarat, India

- Year of Establishment:2014

- Business Type:Manufacturer, Trading Company, Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Acid Proof Tiles,Acid Proof Tiles,Acid Proof Bricks,Acid Proof

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowPhenolic Resin Mortar

Phenolic Resin Mortar is widely used for Acid Resistant Bricks & Tiles lining works as Bedding & Jointing Mortar for Tanks, Floor, Drain, Foundation, Chemical Reaction Vessels, and Neutralization Pit etc.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Phenolic Resin Mortar is widely used for Acid Resistant Bricks & Tiles lining works as Bedding & Jointing Mortar for Tanks, Floor, Drain, Foundation, Chemical Reaction Vessels, and Neutralization Pit etc.

Resistant

It is resistant to Concentrated H2SO4 acid, acid, Non-Oxidizing Acids, Dilute Oxidizing acids, Solvents and Neutral Salts.

Resistant to temperature

170° C (Max.)

Preparation of Mortar

Preparation of Mortar generally consists of Solution & Powder. In order to obtain good working consistency, the average mixing ratio is 1 Pbw of Solution & 3 pbw of Powder. This ratio will slightly vary depending upon the temperature and working conditions.

Prepare small batches of Mortar. Stirrer the Solution thoroughly before use. Place the Solution in a suitable mixing pan and add powder in it. Mix thoroughly with a spatula or Trowel. The mixing operation shall be continued until a uniform mixture is obtained.

Make sure that all the Mortar is used from the mixing pan before another batch is prepared.

Surface Preparation

The cement plastered surface shall be slightly rough in line & level , dry & clean, free from dust, dirt, grease, oil etc., maintaining required slope etc. as no slope can be adjusted or altered in Acid proof lining works.

Setting / Curing

Phenolic Resin Mortar is a Self-hardening due to its chemical reaction which occurs when the Powder & Resin are mixed together.

- An initial setting occurs in 6 to 8 hrs. at 30°C

- Final Setting occurs in 24 to 48 hrs. at 30°C

- Curing time: 7 days at 30°C

Please ensure that no water shall be spilled over the bricks lining works before it completely cured.

Mechanical/Physical property (As per IS-4832 Part-II)

- Working time at 30°C: 20 minute (min)

- Density of cured mortar: 1.8 grm per cc

- Bond strength: 10 Kg.Cm2

- Compressive Strength: 350 Kg/Cm2

- Flexural Strength: 75 Kg/Cm2

- Water Absorption: 1%

Storage Life

- Solution: 2 Months at the temperature 32°C

- Solution: 3 Months at the temperature 27°C

Phenolic Resin is Sensitive to temperature auto polymerization of the resin process is continued at the room temperature, If Resin will gel form Occur it useless for application. When Resin not in use it store in cold area.

- Powder: 6 Months at the temperature 30°C

All two components are stored in cool and dry place under the roof until ready to use it original unopened (Sealed) containers.

Packing

- Solution: 25 Kg. in M.S. Drum

- Powder: 25 Kg. in Plastic Bag.

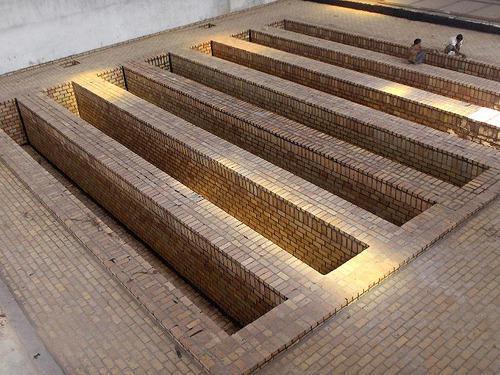

Images