Zentek Electronics & Communication Pvt Ltd

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:2001

- Business Type:Manufacturer

- Main Products:Vehicle Tracking Systems, Security Systems

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

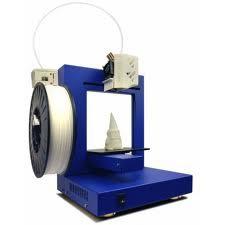

Verify Now3D Printer

Description Model material ABS & PLA Plastic

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Description

Model material

ABS & PLA Plastic

Build size

140W x 140D x 135H mm

Layer thickness

0.15/0.20 /0.25 /0.30 /0.35 /0.40 mm (optional)

Workstation compatibility

Windows XP, Vista, Win 7 & Mac

Size

245W x 260D x 350H mm (9.5 x 10.5 x 14 inch)

Weight

5Kg(11b)

Power requirements

100-240V, 50-60Hz, 220W

Colours

White, Black, Dark Gray, Red, Blue, Nectarine, Fluorescent Yellow

Olive Green, ABS Natural Plastic(Off-White).

3D printer,Personal 3D printer,Mini Desktop 3D printer,Rapid Protypes, 3D printer, 3Dprinter, 3d printer machine for prototype

3D printe, it's easy to use, with feature-rich Software ad Impressive Print quality

We build your part to your specifications and ship it promptly. Our process is based on Fused Deposit Modeling otherwise known as "FDM". This process takes plastic and melts it layer by layer creating the

desired part. During the build process, extra material called "support" may be added to your part in order to allow overhangs or undercuts to be produced This can be removed after the part is finished.

3D Printers are less costly variations of RP technology that are positioned as a design tool to create inexpensive models early in the design process. The ability to produce quick, inexpensive ABS models allows the

designer to model multiple concepts. Physical models produced on a Dimension 3D Printer allow everyone on the design team to review the concepts. In turn, the company gets better feedback, resulting in a better

product. 3D printing allows companies to achieve real time collaboration on a global scale.

ABS is the most commonly used plastic in manufacturing today. Cell phones, television sets, and the majority of car interiors are made of ABS or ABS blends. ABS allows you to build durable and functional

prototypes that can withstand rigorous testing and won't warp, shrink or absorb moisture. ABS models can be drilled, tapped, sanded and painted. ABS is the material of choice by leading manufacturers.

Product Application

1.Product Prototype{Before Factory Make New Mould)

2.Make Samples(Design Studio)

3.Make Models(Medical Institutions)

4.Art Products( Architect /Art master)

5.Make Models For Teaching(Educational Institution)

6.Design Enthudiasts

7.Animation Models / Automobile Models

Images