Weld Aid India

Product Range

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:2000

- Business Type:Manufacturer

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Welding Machines, Industrial Torches

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

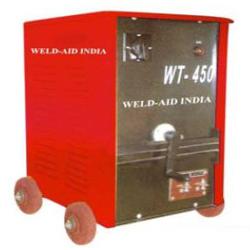

Verify NowMIG Welding Machines

We have a huge assortment of MIG Welding Machines made of superior quality raw material.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We have a huge assortment of MIG Welding Machines made of superior quality raw material. These machines come at very competitive prices and are designed to meet the welding requirements of our clients. We offer these machines in various sizes and types, keeping in mind the diverse requirements. Co2 welding machines and semi automatic mig welding machines are also supplied by us keeping in mind the premium quality. We have now become one of the leading suppliers of mig welding machines in india.

Process :

Gas Metal Arc Welding (GMAW) is referred as Mig welding which is a commonly used high deposition rate welding process. Wire is continuously fed from a spool. Therefore, it is referred as a semiautomatic welding process.

Following are the benefits :

- Higher deposition rates than smaw

- Less operator skill required

- Long welds can be made without starts and stops

- Minimal post weld cleaning is required

- All position capability

Some of the salable features of our product are :

- Welds mild steel, aluminium & stainless steel wire & bronze alloy wires

- Suitable for solid wires as well as flux cored wires

- Easy connection system for torch plugin to wire feederm

- Coarse and fine control for proper selection of voltage

- Sleek & most flexible torch

Technical Specifications

| Model | SP - 250 | SP - 400 | SP - 600 | |

| Welding current | Upto 250 | Upto 400 | Upto 600 | |

| Open circuit | 18 - 38 | 18 - 52 | 18 - 56 | |

| Maximum Continous Welding Current | ||||

| @ 60 % Duty Cycle AMPS | 250 | 400 | 600 | |

| @ 100 % Duty Cycle AMPS | 180 | 315 | 480 | |

| Input SupplyRating | 415/ 3PH, 50 Hz | 415/ 3PH, 50 Hz | 415/ 3PH, 50 Hz | |

| @ 60 % D.C. KVA | 8.8 | 22.5 | 35 | |

| @ 100 % D.C. KVA | 6.5 | 17 | 27 | |

| Cooling | Forced Air | Forced Air | Forced Air | |

| Insulation | F | F | F | |

| Dimension (LxWxH) | 770x440x660 | 830x490x730 | 830x540x730 | |

| Weight KG | 105 | 200 | 840 | |

| Wire size mm | Steel | 0.8, 1, 1.2 | 0.8,1.2, 1.6 | 1.2, 1.6 & 2 |

| Wire size mm | Aluminium | 1.2 | 1.2, 1.6 | 1.2, 1.6 |

| Speed Range | 0 - 18 | 0 - 18 | 0 - 18 | |

| Drive Type | 2 Roll | 2 Roll | 4 Roll | |

| Roll | Spool Size | Spool Size | Spool Size | |

| Overall Dia mm | 300 | 300 | 300 | |

| Bore mm | 50 | 50 | 50 |

Images