Vinayak Road Equipment

Product Range

Fact Sheet

- Location:Gujarat, India

- Year of Establishment:1998

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 5 - 50 Crore

(or USD 1 Million - USD 10 Million) - Main Products:Asphalt Plant, Hot mix Plant

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

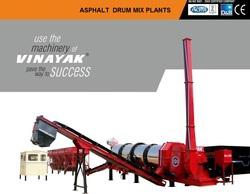

Verify NowCold Aggregate Feeder Unit

In order to meet the diversified requirements of our precious clients, we are actively engaged in manufacturing, exporting and supplying an extensive range of Cold Aggregate Feeder Unit.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

In order to meet the diversified requirements of our precious clients, we are actively engaged in manufacturing, exporting and supplying an extensive range of Cold Aggregate Feeder Unit. Our provided feeder unit is available in the market in various specifications as per the variegated requirements of our valuable patrons. To ensure its quality before the final dispatch, our quality experts test this feeder unit against varied parameters. Additionally, precious clients can purchase this feeder unit from us at cost-effective prices.

Features:

- High performance

- Extremely durable

- Sturdiness

The hoppers have been properly designed with slopes, allowing a constant discharge without bridge forming. The first bin meant for the small size aggregate or dust is fitted with vibratory motor to ensure the free flow. Each hopper is equipped with an adjustable opening door that determines the discharge quantity for the materials capacity in outlet, as a function of specific weight of materials.

The material is drawn out from the hoppers by means of extracting conveyor driven by a preset-able adjustable variable drive motor, coupled with worm gear boxes, that enables to increase or decrease the material output as per the job mix formula requirements. It is also possible to increase or decrease the total capacity without varying the preset settings by means of master control.

The vibratory screen is assembled at the end of cold aggregate feeder for removal of oversized materials.

Images