Shine Success System

Product Range

Fact Sheet

- Verified

- Location:Tamil Nadu, India

- Business Type:Manufacturer

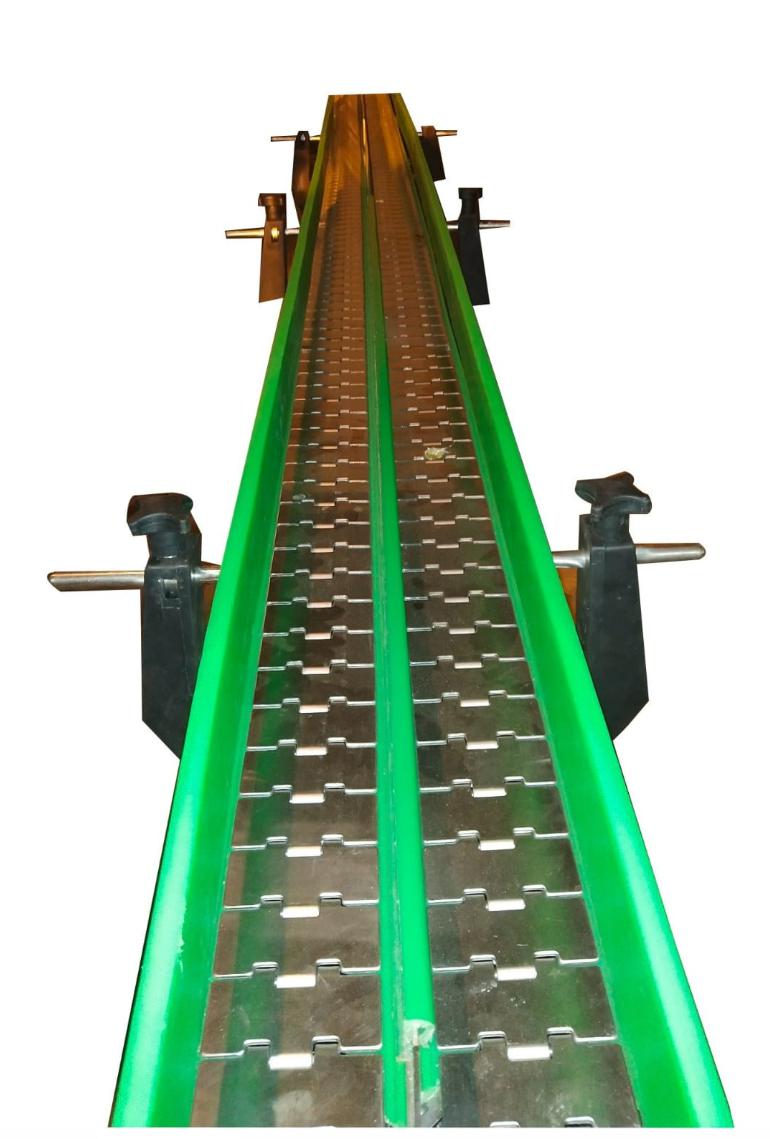

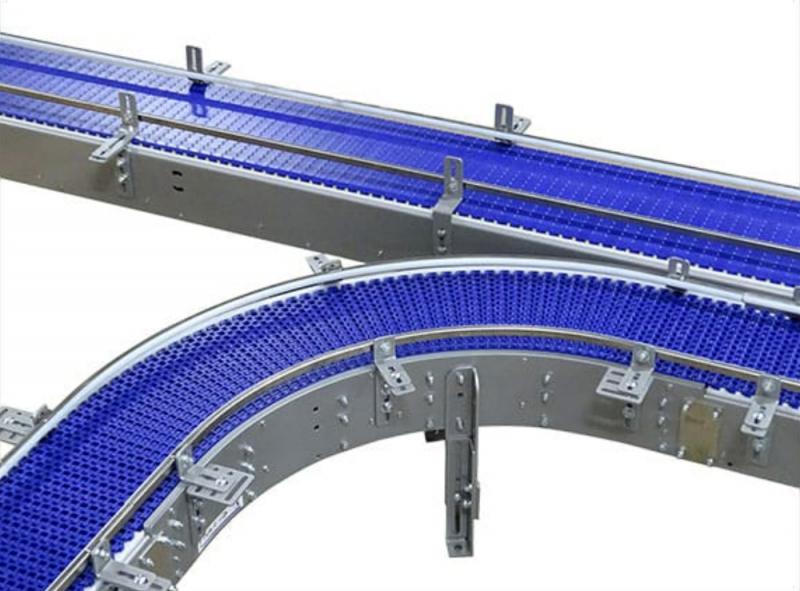

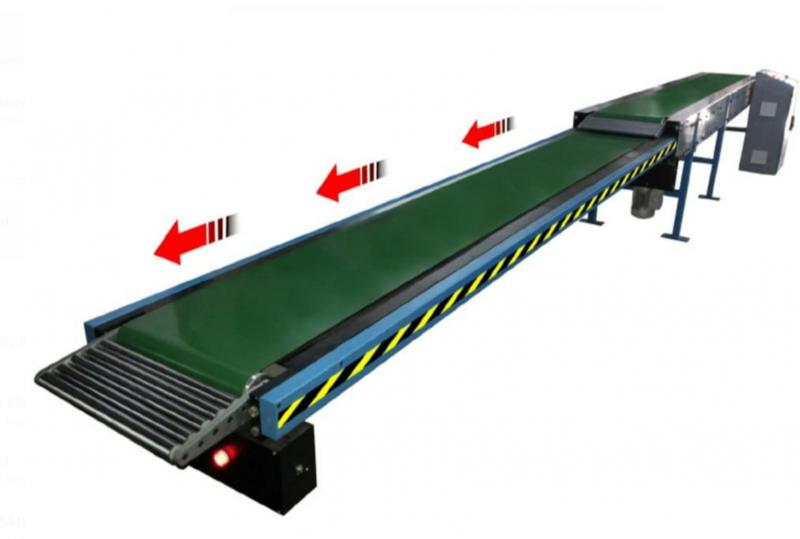

- Main Products:Conveyor

- Reviews & Rating:

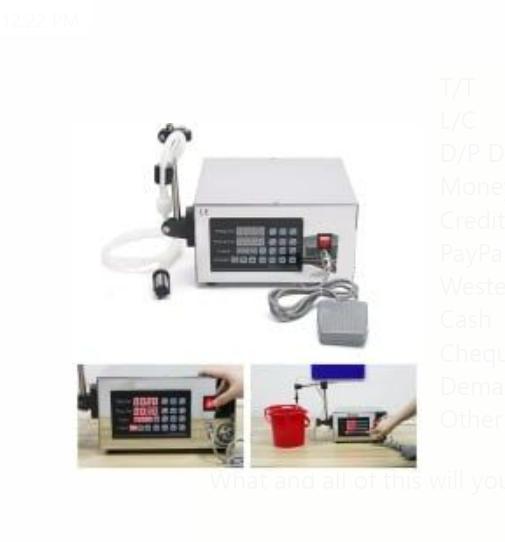

Capping Machine

The Capping Machine automates cap application on containers, ensuring secure sealing and preventing leakage. Used in pharmaceuticals, food, cosmetics, and chemicals, it supports screw, ROPP, lug, and snap-on caps for efficient packaging.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

The CM-1000 Capping Machine is engineered for precision and efficiency in sealing various container types. Its robust stainless steel construction ensures durability and compliance with GMP standards. The machine's versatility allows it to handle different cap styles, including screw-on, press-on, and ROPP (Roll-On Pilfer-Proof) caps, making it ideal for diverse production needs.

Equipped with a PLC control system and a user-friendly touch screen, the CM-1000 offers easy operation and quick changeovers between different cap and bottle sizes. The adjustable torque control ensures consistent capping tightness, preventing product leakage and maintaining quality.

Safety features include an automatic stop function when a bottle is missing or improperly positioned, reducing downtime and product wastage. The compact design saves valuable floor space, and the machine's low noise operation contributes to a comfortable working environment.

Product Application

- Pharmaceuticals: Sealing medicine bottles with child-resistant or tamper-evident caps.

- Food and Beverage: Capping jars, bottles, and containers for sauces, juices, and condiments.

- Cosmetics: Applying caps to bottles containing lotions, creams, and perfumes.

- Chemicals: Sealing containers with cleaning agents, solvents, and other chemical products.

Technical Specifications

- Capping Mechanism: Rotary chuck system with adjustable torque

- Conveyor Speed: Variable, synchronized with capping speed

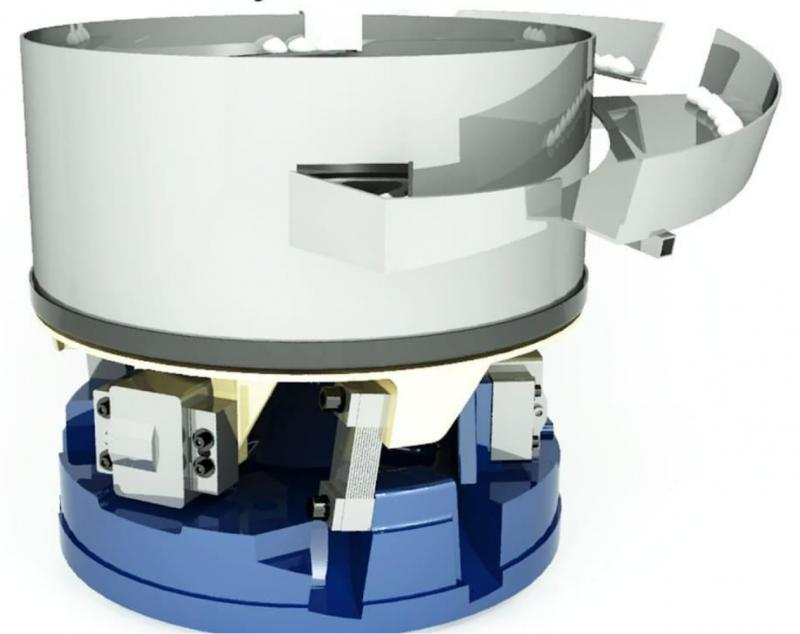

- Cap Feeding System: Vibratory bowl feeder or cap elevator (optional)

- Air Pressure Requirement: 0.6 MPa

- Noise Level: ≤75 dB

- Operating Temperature: 5°C – 40°C

- Relative Humidity: ≤85%, non-condensing

Images