Nivedita Sharma

Product Range

Fact Sheet

- Location:, India

- Business Type:Manufacturer, Exporter

- Main Products:Thermoplastic Road marking Paints,Water borne Road marking pain

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowHot Melt Thermoplastic Road Marking Material Yellow

Excellent retro-reflective properties, resulting in great night visibility. Good adhesion with both asphalt and concrete roads. Excellent incorporation of glass beads. High skid resistance. Durability, heat stability & long lasting product. High

- FOB PriceUSD-1-2-Tons

- Min Order Quantity27-Tons

- Payment TermsNA

Other Details

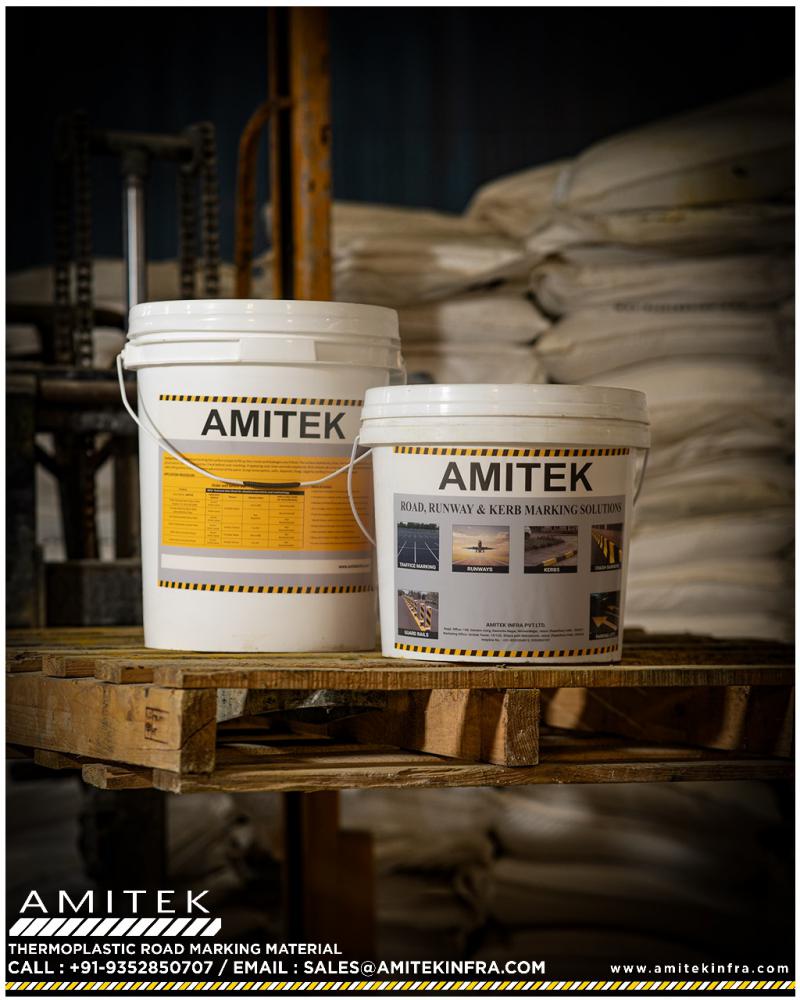

AMITEK INFRA TECHNCAL DATA SHEET AMITEK RETRO REFLECTIVE THERMOPLASTIC ROAD MARKING MATERIAL

PRODUCT DESCRIPTION

Colour: White, Yellow Finish: Gloss / Matt

A versatile road marking paint with excellent day and night visibility & retro reflectivity which provides optimum balance between melt flow and flow resistance to achieve well defined lines as per the desired width & thickness. It has excellent wear resistance and adhesion on both asphalt & concrete surface. Our endeavour is to do continuous research and development of new product meets our customer’s specification all climate conditions worldwide.

AMITEK Retro Reflective Thermoplastic Road Marking Paint complies with BS 3262: Part 1/ 1989 & MORTH 803.4.

AREA OF APPLICATION

Mainly recommended for traffic lane markings, roads, pavements, runways and airfields all over the country areas. Also can be used for relining on previous marks. Highly recommended where high thickness is needed to achieve. Can be used to paint concreate surfaces with primer and asphalt surfaces without primer but ensure there should be no standing and bleeding water in asphalt surface. When used in high trafficked areas the marking must have hardened completely before the area is reopened for traffic.

Don’t show any flaking & cracking

UNIQUE SELLING POINTS

• Whiteness & retroreflective.

• Fast drying thus good flow resistance.

• Heat, colour stability & high skid resistance. • Adaptable to any type of road.

• Cost effective & provides value for money.

• Nontoxic and environmental friendly.

SURFACE PREPARATION

Before application, the surface shall be dry, clean, free from dust, loose particles, salt and grease or oil. Old markings must be checked before over marking. New bituminous surface shall be weathered 4 to 8 weeks before final application. Concrete road or road with poor bitumen has

to be prepared with AMITEK Primer (=0.2 kg/m2). If relining, make sure of the proper adherence and compatibility with pre-existing road marking. If applying over new concrete pavements, remove all curing agents & residue before to ensure correct adherence of the paint possible

for proper adhesion. The application equipment selected should be grade 304 stainless steel or higher. The moisture content of the concrete surface should be checked and ensured to be below 65% when measured with a reliable moisture meter, such as the Sovereign Moisture Meter. The manufacturer will not be liable for failures of adhesion on any polished surface.

Air / Surface Temperature: 5°C to 40°C during application.

Rain Resistance: Rain should not fall 30 minutes prior to expiry of no pick up time. At high air

humidity (> 75% Hrel), the time until safety is reached can be increased.

APPLICATION

Heat the material to 180-200°C in the pre-heater till it transforms into a homogenized liquid. Ensure that the primer is thoroughly dry and void of solvent prior to application of the thermoplastic material. Ensure temperature of 180-200°C and adequate agitation during application. Do not hold thermoplastic above 180°C for more than 6 hours. Do not heat the material above 220°C at any point in the time. Change in colour indicates that the material has scorched owing to overheating and needs to be discarded. Maximum relative humidity must not more than 85%. Ambient temperature more than dew point at least 5°C & wind speed must be lower than 25 km/h. Application machines must be cleaned immediately after use with clean water.

Glass Bead Application: 5 kg/m2 glass beads are required to be dropped onto the paint immediately after paint applied. The glass beads should comply BS 6088 Class B & should be of specified diameter.

Drying Time: Higher temperature may reduce the pass over time. Lower temperatures will increase the pass over time significantly.

STORAGE & STABILITY

12 months after delivery, when kept in tightly closed original packaging in a well – ventilated & covered place at a room temperature between 5 to 30°C, not directly on the floor and not in the vicinity of heating radiators. Material can show a tendency towards sedimentation during transport & storage. For industrial/ professional use only. Keep away from children.

Refer to the MSDS sheet before use.

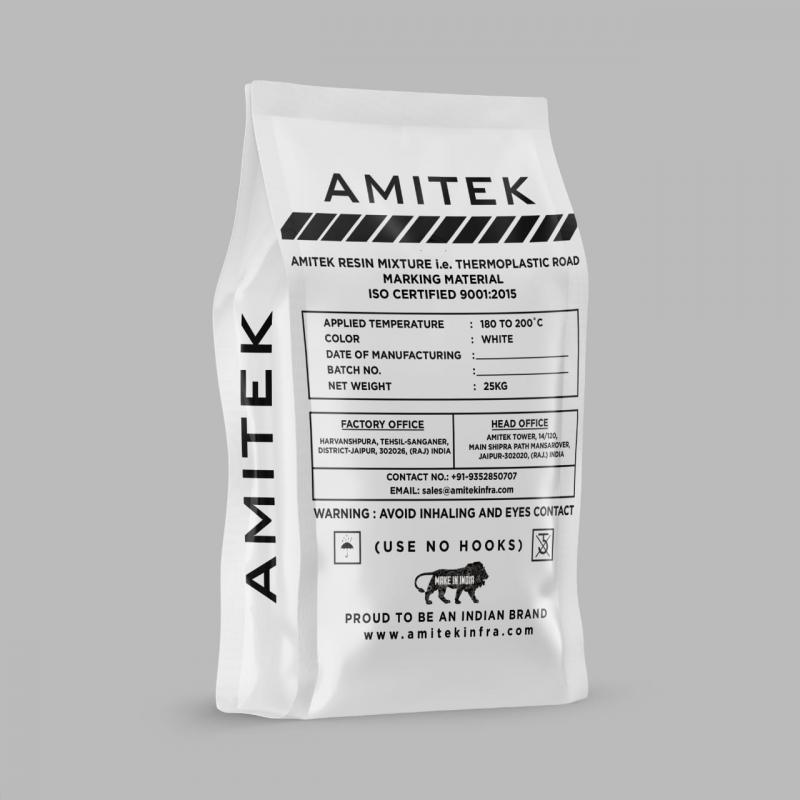

PACKAGING & SHIPMENT

• Packaging: 25 KG PP bags.

• Packaging properly labelled & marked. • No dangerous good for transport

DISCLAMER:

The information above is believed to be accurate & represents the best information currently available to us.However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use, handling and from contact. Users should make their own investigations to determine the suitability of the information for their particular purposes. In no way, Amitek Infra will be liable for

any claims, losses, or damages of any third party or for lost any special, indirect, incidental, consequential or exemplary charge, however arising, even Amitek Infra has been advised of the possibility of such damages.

AMITEK INFRA PVT. LTD.

Images

_207989.jpg)

_207989.jpg)