Lubing India Pvt Ltd

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1996

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Floor Watering System for Turkeys,Floor Watering System for Duc

- Reviews & Rating:

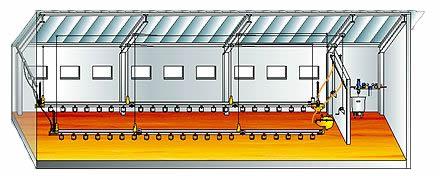

Floor-Watering System for Breeder

We offer a wide range of Watering System For breeder that are made from better quality materials. These poultry equipment are used in various poultry and are in high demand because of their excellent finish and robust construction.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Product Details

- Animal TypeOther

- Grade StandardFeed Grade

- UseChicken

Other Details

The central element of the dewatering system is the TOP-Nipple or TOP-Combinipple, ensuring optimum water flow for each animal age.The combination of nipple and goblet ensures a dry fertilizer. The correct height depends on the size of the animals: They should have to stretch slightly to reach the nipples. Each delivery system includes a table in height, which makes it easy to find the right height of the drinking line from the first day.The LUBING system for broiler chickens consists of: Water supply, Watering elements, Suction unit, Suspension.

Water supply:

The main water supply ensures optimum water quality for a long service life of drinking troughs. Water should have the quality of drinking water. In all cases, the water must be filtered. Water flows from the main water supply through pressure regulator or ball tank with integrated flushing system in drinking lines. Both versions are available for front or intermediate installations.

Drinking Elements:

The beverage lines are supplied in assembled elements of 3m length. These elements must be coupled to the length of the house.

Blown unit:

At the end of each beverage line, a bleed valve is installed. All valves of the breather valve are closed during rinsing, which can be started by hand or by the automatic flushing system.

Suspension:

The beverage lines are suspended by hangers, which are glued to the aluminum profiles every 3 m. These hangers are connected by ceiling pulleys to the central lifting cable. The drinking line can be adjusted to the desired height by hand winch or ceiling winch and can be lathed up easily to the ceiling to empty or clean.

Images

_16034.jpg)

_16034.jpg)