Heatco

Product Range

Fact Sheet

- Location:West Bengal, India

- Year of Establishment:1976

- Business Type:Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Custom Built Heaters, Standard Heaters

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

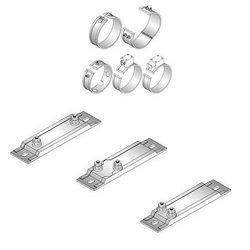

Verify NowTubular Heating Element

The most versatile of all electric heating elements, the tubular heater is capable of being formed into virtually any configuration.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

The most versatile of all electric heating elements, the tubular heater is capable of being formed into virtually any configuration. The basic design consists of a helical coil of nickel-chromium resistance wire embedded in a magnesium oxide insulating material. The cross section design of the metal sheath assures maximum strength and rigidity. The tubular design also permits ready bending and forming to fit a wide range of applications, without damage to the heating coil or insulation material.

Copper Sheath: For water heating & for heating water solutions which are non-corrosive to copper.

Steel Sheath: Immersion in oils, molten salt baths, alkaline cleaning solutions, tars and asphalt. Suitable for casting into aluminum.

Stainless Steel Sheath: Corrosive liquids, food processing equipment.

Incoloy Sheath: Air heating, radiant heating, cleaning and degreasing solutions, plating and pickling solutions, corrosive liquids.

Other sheath materials are also available for application considerations. Commonly specified are SS 304, SS 316, SS 321 & Incoloy tubes along with titanium for severely corrosive solution heating.

Images