Grewal Industries

Product Range

Fact Sheet

- Location:Punjab, India

- Year of Establishment:1973

- Business Type:Manufacturer, Distributor / Wholesaler

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Power & Forging Screw Presses, Forging Screw Press

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

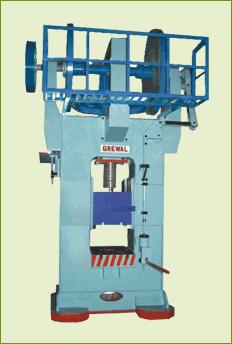

Verify NowFriction Screw Press(Down Stroke)

Grewal Friction Presses are used for forging, stamping, embossing, pressing, sizing, bending, coining, shallow drawing, fire bricks, non-ferrous, hot and cold forging operations etc.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Grewal Friction Presses are used for forging, stamping, embossing, pressing, sizing, bending, coining, shallow drawing, fire bricks, non-ferrous, hot and cold forging operations etc. These Friction Screw Presses are provided with two friction discs and are balanced and mutually adjusted by secured nuts with a fly-wheel in between them.

The body of the press is of steel plate, fabricated with utmost care. It is of box-type design. All forces including twisting of press are taken care of properly. After welding the body of the Press is glowed free from tension, therefore, the usual danger of breakage is avoided.

The screw is made of high quality alloy steel and heat treated to have high hardness and elasticity. Flywheel revolution produces screw revolution and its movement is through bronze nut. Nut is pressed into press frame and is able to withstand greatest stress and to transmit it to the frame.

If desired a safety flywheel and pneumatic control device can be installed at extra cost. The construction of this fly wheel absolutely prevents the dangerous rebounding which can cause spindle breakage and further damages.

Common qualities of these presses are good construction. best material. simple and easy handling. The impact velocity approaches that of drop hammer. therefore, longer die life and low foundation cost is achieved. They are used wherever quality and safety are required.

SPECIAL FEATURES

The cost of machine is low compared to other makes and foundation expense is also minimum.

Dies of forging have long life due to high accuracy of the machine.

The cost of development , manufacturing and replacement of dies are much low.

Great forging accuracy is achieved because of the free stroke.

Additional energy can be applied to the same die impression by making several blows.

The heat contact time is considerably less than the crank type forging presses and knuckle joint type presses.

Cost of repair after years of hard usage is low. A semi skilled worker can operate the machine easily.

Technical Specifications

| TECHNICAL SPECIFICATIONS OF FRICTION SCREW PRESSES (DOWN STROKE) | |||||||||||||

| Model | Capacity in Tons | Dia of Screw mm/Inch | Stroke of Ram mm/inch | Number of Strokes P-Minute |

Size of Table mm/inch |

Table to Ram (Max.) mm/ inch | Table to Ram (Min.) mm/ inch | Bore in Table mm/inch | Bore in Ram (Shank Dia) mm/inch | Dimension of Ram mm/inch | Height mm/inch | Appx. Wt. in Kgs. | H.P. Reqd. / R.P.M. |

| GFSP-30 | 30 | 80/3.25 | 180/7 | 30 | 305x280 12x11 |

330/13 | 150/6 | 75/3 | 40/1.50 | 225x225 9x9 | 2250/8'-4" | 2000 | 5/1440 |

| GFSP-50 | 50 | 100/4 | 200/8 | 25 | 380x355 15x14 | 355/14 | 150/6 | 75/3 | 40/1.50 | 300x300 12x12 | 2850 9'-4" | 3000 | 7.50/1440 |

| GFSP-100 | 100 | 125/5 | 280/11 | 20 | 475x450 19x18 | 450/18 | 175/7 | 100/4 | 50/2 | 350x350 14x14 | 3150 10'-4" | 4000 | 10/960 |

| GFSP-150 | 150 | 150/6 | 330/13 | 18 | 525x500 21x20 | 530/21 | 200/8 | 125/5 | 65/2.50 | 400x400 16x16 | 3750 12'-4" | 6500 | 15/960 |

| GFSP-200 | 200 | 165/6.50 | 355/14 | 15 | 550x525 22x21 | 560/22 | 200/8 | 125/5 | 65/2.50 | 425x425 17x17 | 4000 13'-4" | 7500 | 20/960 |

| GFSP-300 | 300 | 200/8 | 405/16 | 12 | 625x600 25x24 | 635/25 | 225/9 | 150/6 | 75/3 | 475x475 19x19 | 4400 14'-6" | 11000 | 30/960 |

| GFSP-400 | 400 | 240/9.50 | 460/18 | 10 | 700x700 28x28 | 710/28 | 250/10 | 150/6 | 75/3 | 525x550 21x22 | 4725 15'-6" | 16500 | 40/960 |

|

(IN VIEW OF CONTINUOUSLY DEVELOPMENT WE RESERVES THE RIGHT TO MODIFY THE DESIGN AND DIMENSIONS WITHOUT NOTICE) |

|||||||||||||

Images