Forech India Ltd

Product Range

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1972

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Material Handling Equipments, Couplings

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowPatterned Sheet Pulley Lagging

Certified by ISO 9001:2000 certification, we are considered as the pioneer & foremost manufacturer and exporter of Patterned Sheet Pulley Lagging.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Certified by ISO 9001:2000 certification, we are considered as the pioneer & foremost manufacturer and exporter of Patterned Sheet Pulley Lagging. Suitable for controlling belt slippage and preventing material build up, these pulley laggings are widely used in varied industries. Our entire range of Patterned Sheet Pulley Lagging is manufactured by our expert professionals using modern machines & equipments. Available in diverse specifications, these pulley laggings can be customized to meet the specific needs of our clients.

Features:

Chemical resistance

Unmatched quality

Impeccable finish

Further Details:

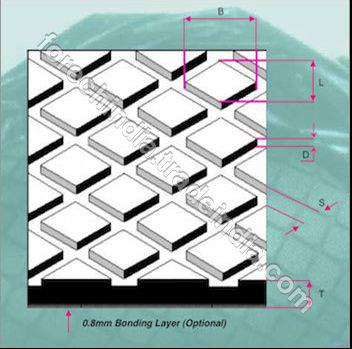

Pulley Laggings, with specially developed rubber materials and their patterned surfaces have proved to be very effective in water shedding.

Offering

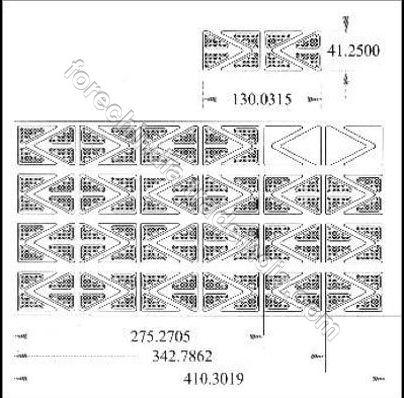

Forech offers a comprehensive range of Patterned Sheet Pulley Laggings to suit every conceivable conveyor installation. The Pulley Laggings offered by Forech are produced in different thicknesses, rubber qualities and patterns to ensure selection of the most appropriate type, to suit all application requirements.

The Sheet Pulley Laggings offered by Forech come with CN Bonding Layers for better adhesion levels. The profiled patterns on the top surface, in diamond or square embossing improve belt grip and tracking on conveyors, while reducing belt wear. The Sheet Pulley Lagging is available in various grades of rubber, including N, FRAS and White Nitrile for packaging and food stuff carrying belts.

Benefits

Easy to install

Minimum wastage and economically priced

Reduced adhesive use due to Bonding Layer

Shorter lead times

Maintains friction grip under unfavourable drive conditions

Increased friction coefficient between the pulley and the conveyor belt

Extremely helpful while running in wet conditions

Prevents dirt build up in pulleys

Images