Floret

Product Range

Fact Sheet

- Location:Karnataka, India

- Year of Establishment:2013

- Business Type:Distributor / Wholesaler

- Turnover:Rs. 50 - 500 Crore

(or USD 10 Million - USD 100 Million) - Main Products:Apparel Products, Food Products, Machinery Products

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

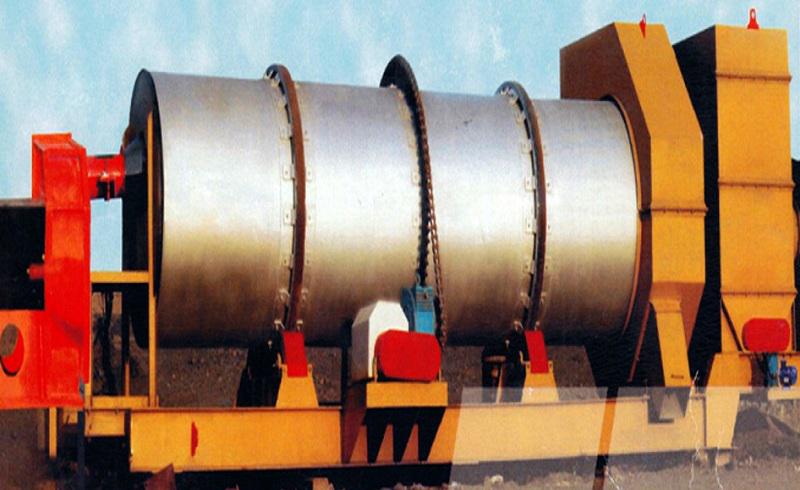

Verify NowActivated Carbon Processing Machine

Our qualified team of professionals have expertise in manufacturing, supplying and exporting a wide range of activated carbon. The products offered are suitable for various applications that can be acclaimed by customers for their precise use.

- Min Order Quantity5-Pieces

- Payment TermsCash,Cheque,Demand Draft

Product Details

Type

Activated Carbon Processing MachinePrice

NegotiableDelivery

On Time DeliverySupply Type

OEMPrice

NegotiableCondition

NewTemperature Range

900°C -1100°C

Other Details

Activated Carbon is the carbon produced by activation of any carbonaceous material such as coconut Shells, bamboo, wood chips, sawdust, coal, lignite, paddy husk, etc. In the northern region of the country, activated carbon is produced mainly from wood charcoal, whereas in the southern region including Kerala, it is made from charcoal of the shell of Coconut that is available aplenty. Shell-based activated carbon is extensively used in the process of refining and bleaching of vegetable oils and chemical solutions, water purification, recovery of solvents, recovery of gold, in gas masks for protection against toxic gases, in filters for providing adequate protection against war gases/nuclear fall outs, etc.

(1) Pre Activation

(2) Activation

(3) Post Activation

The process of activation is carried out in two stages. Firstly the coconut shell is converted into shell charcoal by carbonization process which is usually carried out in mud-pits, brick kilns and metallic portable kilns. The coconut shell charcoal is activated by reaction with steam at a temperature of 900°C -1100°C under controlled atmosphere in a rotary kiln.The reaction between steam and charcoal takes place at the internal surface area, creating more sites for absorbtion. The temperature factor, in the process of activation is very important. Below 900°C the reaction becomes too slow and is very uneconomical. Above 1100°C the reaction becomes diffusion controlled and therefore takes place on the outer surface of the charcoal resulting in loss of charcoal.

Images