Durga Filters (P) Ltd.

Company Overview

Fact Sheet

- Location:Uttar Pradesh, India

- Year of Establishment:2005

- Business Type:Manufacturer, Distributor / Wholesaler

- Turnover:Upto Rs. 50 Lakh

(or Upto USD 100 K) - Main Products:Automotive Air Filters

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCompany Info

Overview

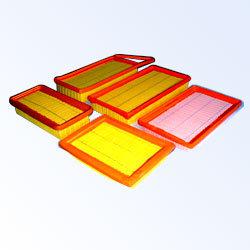

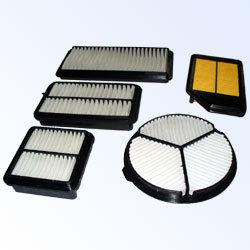

Established in the year 2005, at Ghaziabad, Uttar Pradesh, we “Durga Filters,” are engaged in manufacturing and supplying a wide range of filters. Previously we are dealing in air filters with 32 products and with time we expand our business. In the first year, we have achieved an annual turnover of 1.24 lakhs. Our product range includes: automobile air filters, oil filters, diesel fuel filters, petrol filters, foam filters, panel type pu, plastic moulded filters, round black type filters, round orange type filters. We are led by “Mr. Pintoli Kumar Parjapat,” who has 15 years of domain expertise and helped us to meet the emerging market challenges. To support him, we also have a team of engineers, industrial designers and other associated workforce who assist us in manufacturing filters as per the requirement of our customers. Further, our consistent approach has also helped us to achieve an annual turnover of 12 crore. Quality Assurance Being an ISO 9001:2000, we give priority towards manufacturing qualitative range of oil, fuel, air and foam filters as per client's specifications. Our quality checking unit assist us in checking the quality of the procured raw materials, the dimensional accuracy of the manufactured filters as well as other features. Furthermore, we use qualitative raw materials like filter paper, jali, adhesive chemical, PP Dana and others in the manufacturing of the products. This ensures that our range can provide optimum performance standards to the end users. The parameters on which our range is quality checked include : Dimensional accuracy Cold strength Filtration effectiveness Particle retention size Effect on flow rate Turbulence reduction Erosion resistant Why Us? The key factors for which we remain ahead of the other market players include : • ISO 9001:2000 certified organization • Qualitative range of products • Well equipped manufacturing unit • Experienced workforce • Competitive prices • Timely delivery Clientele Our motto is to give complete customer satisfaction by offering them with qualitative range of air, oil, foam and fuel filters. Furthermore, our filters are cost effective and delivered within the specified time frame, which has also helped us to make many quality conscious clients all across the globe. Some of our valuable clients are as follows : John Fowler Pvt. Ltd. Purolator India Ltd. VIR Auto Manufacturing Co. T.V. Super Industries MHB Filters India Pvt. Ltd. Lumax Automotive Sys. Pvt.Ltd. Rohit Industries J.S Automobiles Elofic Industries Ltd. Radiant Filteration sys.Pvt. Ltd. Arroowhead Filteration Equipment comp. Spark profile Pvt. Ltd. Warehousing, Packaging And Timely Delivery Our spacious warehousing facilities enable us to safely store our range of filters and the raw materials used in the production process. Furthermore, we also have with us facilities for ensuring qualitative packaging for our range. For this, we use qualitative material to ensure safety of the products during the transit period. In addition to this, we also have tie ups with reputed transportation companies, which help us in timely delivering our range to the end users. Application Areas Some of the applications areas of our range include : Automobile industry Agriculture Earthmoving Marine industry Aviation industry Industrial heating Petrochemical industry Our Team We have with us services of a team of experienced engineers, industrial designers, administrative personnel and other supporting staff to look after the entire production process. They are well versed with latest technology and the changing market scenario, which help us to deliver the filters as per the emerging industry demands. Manufacturing Facility Our well equipped manufacturing facility comprising of modern machines and tools is spread over an area of 1250 meters. It enables us to produce international quality standard fuel, air, oil and foam filters. Further, the raw materials are sourced from reputed vendors to ensure the durability and optimum performance of our range at client's end. Some of the activities, which takes place at our manufacturing unit include : Receiving customer order Purchasing of raw material Inspection of incoming material like aluminum locking, jali folding, tacking etc Chemical mixture Heating (Temp 60º C ) Assembling Final inspection Packaging Dispatch Further, we have also installed modern machines and equipment at our manufacturing unit, which include : Injection molding Coil machine Rotary machine Oven Spot welding machine Jali golai machine Locking machine PU machine Air compressor Generator Plastic die Metal die Future Plan To export our range and purchase new plant, machinery and latest technology to increase our production Products We Offer We are an ISO 9001:2000 certified organization and focus on designing and developing a wide range of filters. Manufactured from superior grade of raw materials like filter paper, jali, adhesive chemical, PP Dana to ensure durable performance of our range at client's end. Our range include : Automobile Air Filters Oil Filters Diesel Fuel Filter Petrol Filters Foam Filters Panel Type PU Filters Plastic Moulded Filters Round Black Type Filters Round Orange Type Filters Research And Development With our sound research and development structure, we consistently work towards delivering the best possible outputs to our clients. Our R&D department have a perfect blend of CAD technology and qualified development experts who develop new range of products as well as work for bringing improvements in existing product range. Our laboratory is also fitted with world class testing facilities that helps in checking all the inputs and outputs of filters as per international quality standards. R&D team conduct following test on individual product : Filter paper micron rating Pressure drop & flow rate Filtration efficiency & life