Dr Polymers Ltd

Product Range

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1978

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 - 500 Crore

(or USD 10 Million - USD 100 Million) - Main Products: Industrial Polymers, Eethylene Vinyl Acetates

- Reviews & Rating:

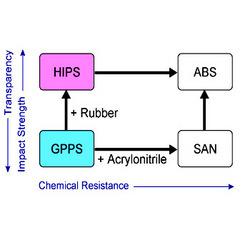

Polystyrene- HIPS, GPPS

Our clients can avail from us high quality Polystyrene- HIPS, GPPS that easily gets molded between 30C to 50C. One of the most commonly used kind of plastics, this polystyrene can be casted into various molds with fine details.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Our clients can avail from us high quality Polystyrene- HIPS, GPPS that easily gets molded between 30C to 50C. One of the most commonly used kind of plastics, this polystyrene can be casted into various molds with fine details. Owing to its distinctive properties, it is used to make diversified products including disposable cutlery, plastic models, CD & DVD cases, smoke detector housings and many more.

Injection Molding:

Recommended melt temperature of 180-280 C

For thin wall objects molded at short cycle times it could be useful to cool down the mold down to 10 C

Mold shrinkage lies between 0.4 and 0.7% depending on the grade used

Extrusion :

High viscosity grade are ideal for extrusion

Melt temperature of 180-220 C

Pre-drying for injection molding with a vented cylinder is not required, however if drying is needed then 4 hours at 80 C is sufficient

Signs of moisture are stripes, streaks or bubbles

Images