Dr Polymers Ltd

Product Range

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1978

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 - 500 Crore

(or USD 10 Million - USD 100 Million) - Main Products: Industrial Polymers, Eethylene Vinyl Acetates

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowPC Polycarbonate

Our clients can avail PC Polycarbonate, which is appreciated for easy processing, molding and transformation. Often used for transparency, toughness and heat resistance,

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Our clients can avail PC Polycarbonate, which is appreciated for easy processing, molding and transformation. Often used for transparency, toughness and heat resistance, it finds application in chemical industry and for making engineering and commodity plastics. As attractive as plastic, this polycarbonate easily replaces glass and metal in applications where temperature does not exceed 125 C. Before processing, this polycarbonate is dried at 120C using appropriate dryers.

Strength :

Optical clarity

Impact strength

Thermal resistance (up to 125 degrees)

Food contact

Flame retardant

Weather-ability

Bio-compact-ability

Electrical conductivity

Applications:

Packaging

Sports and leisure

Safety equipment

Consumer goods

Electrical and electronics

Toys

Construction glazing

Optics

Medicals

Automotive

Lightning and glazing

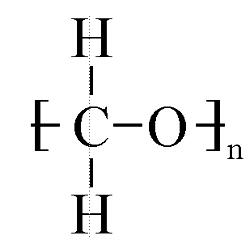

Processing temperature: 180 to 230 C

Thermal damage may occur above 230 C unless the residence time in the cylinder is kept short

High thermal stress during processing will result in the formation of formaldehyde (highly odorous)

Pre-drying is not necessary but can be carried out at 110 C for 2 hours as the material has become moist or if the uniformity of the material needs to be improved

Images