Dr Polymers Ltd

Product Range

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1978

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 - 500 Crore

(or USD 10 Million - USD 100 Million) - Main Products: Industrial Polymers, Eethylene Vinyl Acetates

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

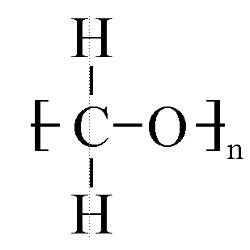

Verify NowPMMA Polymethylmethacrylate

We are instrumental in offering highly resistive PMMA – Polymethylmethacrylate, which is an economical alternative to ploycarbonates. With normal cylinders pre drying of granules for up to 8 hours at 70-100 C is recommended whereas with vented cyli

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We are instrumental in offering highly resistive PMMA – Polymethylmethacrylate, which is an economical alternative to ploycarbonates. With normal cylinders pre drying of granules for up to 8 hours at 70-100 C is recommended whereas with vented cylinders, it can be processed without any drying. If damp granules are processed, they form surface defects and blisters. Sourced from leading manufacturers, it is appreciated by our clients due to its moderate properties, transparency, easy handling & processing, and low cost.

Injection Molding:

Melt temperature : 200- 250 C

Mold temperature : 40 – 80 C

High injection pressures are needed because of poor flow properties and it may be necessary to inject slowly to get the correct flow

Extrusion:

Extrusion temperature: 180 – 250C

Recommended degassing screw with an L/D ratio of 20 –30

Images