DISH INDIA PRIVATE LIMITED

Company Overview

Fact Sheet

- Location:New Delhi, India

- Year of Establishment:1994

- Business Type:Manufacturer, Business Services

- Turnover:Rs. 5 - 50 Crore

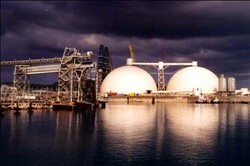

(or USD 1 Million - USD 10 Million) - Main Products:Pressure Vessels, Industrial Boilers

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCompany Info

Overview

About Us Established in 1994 after partition from its 16 years old sister concerned, Dish India is having experience of 35 years in the field, in form of its Chairman Director Mr. Vinay Gupta (man behind introduction of Dished-Ends manufacturing in North India). The company enjoys the sales volume amounting in millions. And, besides covering domestic markets, its products are also being exported to Various Countries. The Company is one of the only few established companies capable of manufacturing Dished-Ends Up to 140mm Thickness (In-house) and taking Heavy Rolling and Fabrication Jobs Up to 100mm thickness (In-house) along with manufacturing of High Pressure Boilers, Cones, Spheres & Pressure Vessels. Each Project / Job handled by Dish India, planned & executed by a team of professionals headed by a Project Manager consisting QC Engineer, Project Engineer, Design Engineer and Electrical & Instrument Engineer (where applicable), who co-ordinate with our In-House team of support from procurement and production department and out-source for any particular requirement. Dish India has over the years built up a proven track record of reliability and high quality work. Treating the customer’s objectives as our own, exceeding their expectations and completing every project on time and within budget are qualities that have earned the company a reputation for Total Quality within the local industry and worldwide. Since its incorporation the company has participated in several major projects jobs locally and overseas, achieving an unblemished record of on-time delivery, It has also taken on difficult projects with exacting specifications and tight deadlines. Thanks to its broad experience over these years in industry, its excellent quick - response record and knowledge of the Asia-Pacific region the company is uniquely positioned to win over clients and new projects. Quality Conformity We are an ISO 9001:2000 certified company, and are successfully offering a wide range of Dished-Ends, Industrial Boilers, Process Boilers, Grate Fired Boilers, Waste Heat Recovery Boilers, Pressure Vessels, Sphere, Cones, etc. Moreover, we also have a quality control departments consistently working to ensure that whatever we manufacture is in accordance with standards and our buyer’s requirements. Our quality controllers stringently test every stage of production starting from the procurement of the material to its final delivery. Our Goal With a high degree of expertise and experience in the Industry and its base of loyal customers Dish India has carved a niche for itself in a highly socialized market. It has positioned itself as a reliable and competent partner serving the specialized needs of its customers. The company though cannot claims to be in the league of the giant multi-nationals. However, compared to other local companies in the same industry, based on job capability and performance, it can be considered among the leaders in its category, in the Country. Our company has always been eager to establish long term business relations with its customers from across the globe and we hope that our prospective clients will give us a chance to serve them with a huge range of our quality products such as boiler plates, boiler quality plates, dished ends, single piece dished ends, industrial boilers, process boilers, grate fired boilers, waste heat recovery boilers, zinc pots, etc. We value you & your time. Our Advantage We also undertake various types of Pressing & Bending Jobs on Hydraulic & Rolling Machines. The Company is one of the only few established companies capable of manufacturing Dished-Ends Upto 140mm Thickness (In-house) and taking Heavy Rolling or Fabrication Jobs Upto 100mm thickness (In-house). Aim / Vision / Mission The Management is totally committed to maintaining & constantly improving its Quality, Occupational Health & Safety Management System & ensuring adequate resources are allocated to this. Management ensures compliance to legal & statutory requirements & ensuring all customers’ needs are achieved. The Management promotes the principle that every employee is responsible for the quality of work one produces & ensuring the safety of each individual employee. The Management is open to exchange Quality, Occupational Health & Safety information & knowledge by interested parties as deemed appropriate & shall make the policy acceptable & available to all employees & any enthusiastic parties.