Devaki Reinforced Plastics

Company Overview

Fact Sheet

- Location:Karnataka, India

- Year of Establishment:1983

- Business Type:Manufacturer, Exporter, Business Services

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Chemical Skids, EMI Shield

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCompany Info

Overview

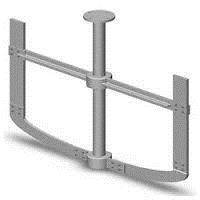

We, Devaki Reinforced Plastics were established in the year 1983 and are primarily engaged in manufacturing, supplying and exporting a wide range of Precision Machined Components, Chemical Skids, Chemical Agitators, Ducting Systems, Mist Eliminators, Nacelle Cover, EMI Shield, Chemical Processing Tanks, Industrial Scrubber, Industrial Blowers, Fuming Chambers, Conductive Coatings, Simulator Replica Models & Security Cabins.Registered as a private limited company,we are led by our Founder M Ramachandran Nair and are successfully monitoring a recommendable growth in the concerned sector. Well skilled manpower adhering to spirit of innovating developed range of products,utilize their industrial expertise in fabricating equipment with reduced maintenance cost. Our well managed manufacturing unit enables us to manufacture desired equipment but also help us in achieving maximum customer satisfaction. Further, time bounded deliveries, hard work and dedication towards achieving maximum client satisfaction are two of the pillars of our organization that have led us in sailing our boats safely in the ocean of this highly competitive industry.We procure high quality raw material from reliable names across the globe for manufacturing and exporting a varying range of products. Our wide range encompasses of Precision Machined Components, Chemical Skids, Chemical Agitators, Ducting Systems, Mist Eliminators, Nacelle Cover, EMI Shield, Chemical Processing Tanks, Industrial Scrubber, Industrial Blowers, Fuming Chambers, Conductive Coatings, Simulator Replica Models & Security Cabins. Each range that we offer is appreciated for its respective features which are enlisted below: Industrial Process Equipment: High performance Long serviceability Dimensionally accurate Hygienic Compact designs Wind Mill Nacelle Cover, Security Cabins, Chemical Skids, Simulator Replica Models and Precision Machined Components Accurate speed of nacelle cover Easy to install and capacious security cabins Dimensionally accurate frame work of chemical skids Light weight, easy to use and install Dimensionally accurate Apart from manufacturing a wide range of products, we also offer effective installation and other services for our range. We undertake machining jobs for precision machined components and perform conductive coatings to cater to the wide requirements of our clients. Our entire range of products and services is customized as per the specifications of our clients and thus we have gained an edge over our clients. Quality Assurance;Quality accomplishment of a project is the main aspect of our production division.The status of a quality oriented company comes with our endeavor to ensure superior quality at each and every production stage. Quality checks are conducted to ensure that the products it deals into match international quality standards which makes us ISO 9001:2000 certified. We have a team of quality personnel who keeps a close check on the whole manufacturing process right from the procuring raw material till the final dispatch of the equipment. These personnel conduct quality tests at our quality testing unit on the following parameters: Industrial Process Equipment Performance Service life Dimensional accuracy Hygiene Designs Wind Mill Nacelle Cover, Security Cabins, Chemical Skids and Simulator Replica Models Speed Installation Dimensional accuracy Weight These checks are conducted at regular intervals on randomly picked finished samples to ensure that delivered should be in compliance with the highest standards of the industry.