Chandni Industries

Company Overview

Fact Sheet

- Location:Uttar Pradesh, India

- Year of Establishment:2003

- Business Type:Manufacturer, Distributor / Wholesaler

- Turnover:Rs. 50 Lakh - 5 Crore

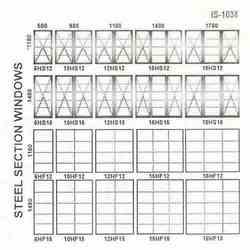

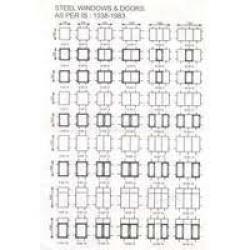

(or USD 100 K - 1 Million) - Main Products:Pressed Steel Windows, Steel Section Windows

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCompany Info

Overview

About Us We are pleased to introduce our firm Chandni Industries the oldest and the leading manufacturer of Steel Windows, Section Steel Window, Pressed Steel Door Frames, Steel Door Frames, Steel Doors & Windows, Pressed Steel Windows, Steel Frames, Steel Section Windows, Z Section Steel Windows, Steel Windows, Steel Section Doors, Steel Doors, Steel Section Ventilators and Steel Ventilators. We are in position to supply at a short notice, any type and design of windows and doors for residential, commercial or industrial buildings as per your requirements. We are supplying our product per ISI specification since 30 years to various Government department. Such as M.E.S. irrigation and other department to entire satisfaction of the officers concerned. They have .appreciated our quality and timely supply we have installed sophisticated equipment and plants such as Rush butt welding tenon and riveting, grinders, staff for technical and non-technical work as well as skilled labour We will not hesitate in writing that our product is highly appreciated due to lull quality control & timely supply. We have good capacity to supply the material in bulk as per the requirement. We assure you our most competitive prices, prompt supply and superior quality of above all. With a hope of your valuable orders. Thanking you and assuring you our best services at all the times. Company Profile Basic Information Business Type Supplier Manufacturer Ownership & Capital Year of Establishment 2003 Ownership Type Sole Proprietorship (Individual) Trade & Market Annual Turnover Rs. 2 - 5 Crore ( or US$ 400 K - 1 Mn Approx.) Team & Staff Total Number of Employees 26 to 50 People Product Portfolio We are a reputed manufacturer and supplier of the best quality Windows and Doors from pressed iron. At our state of the art facility, we adopt sophisticated technology to manufacture windows and doors of standard dimensions or as per client request. Our product range includes Pressed steel window Pressed steel door frames Z section steel windows Our entire range is manufactured using solid and hot-rolled steel section. Moreover the strength of steel coupled with the welded fabrication enables us to produce frames and ventilators that does not crack or break. Customization Facility Backed by an sophisticated manufacturing facility, we offer our clients with the customization option of our products according to their specifications. This is possible because our experts are able to get the exact specifications from the client for the product and are able to manufacture the same for them. The entire customization process is a very important stage for us as this gives us an opportunity to add extra dimensions to our standard product range and make a product that the client can use with satisfaction. To deliver customized products we following these rules: Design Dimensions Other specifications Manufacturing Facility The manufacturing unit has the most sophisticated machinery and grinding machines that ensure top-quality product. This unit is also laced with an in-house designing unit helps us develop our products to perfection. Additionally, our adaption of the latest Auto Cad ensures we are working on the most flawless designs. The manufacturing unit is the largest units of our facility and houses the sophisticated machinery. The machines used in the production process are: Lathe machines Cutter sets Milling Machines Surface grinding machines Grinders Flush Butt Welding Plant Hand Angle Grinder Heavy Duly Sheet Bending Machine for Profile "A", "B", "C" Dipping tank For Painting Flush Butt Welding Plant Tenon Riveted Machine Arc Welding Set 150 Amp to 350 Amp Drilling Machine 1mm to 25mm Hole Capacity Bench Grinder 2 HP Power Press Capacity 40 Ton, 50 Ton Power Press Capacity 20 Ton 8. Hand Grinder GQ-6 Hand Angle Grinder Heavy Duty Sheet Bending Machine for Profile "A", "B", "C" Threading Drill Machine type l mm to 10 mm Threading Wheel Grinder Cutting Machine Special Section Cutting Dipping tank For Painting Testing Equipments S. no. Equipments Remark. 1 Weighing Machine 0-5 Kg 2 Digital Vernier L.C.0.01-200mm 3 Vernier Caliper L.C.0.01-200mm 4 TP Wire Gauge 0.19-7.62mm 5 Measurement Tape 05-5000mm 6 Micro Meter L.C.0.01-25mm 7 Magnificent Glass 5x Magnification 8 Microscope 100x Magnification 9 Alcometer A.A. Pen Type 10 Thread Gauge J(J(MSx0.8 150-62) NOGO(M5 x0 8 -62; D6829 11 Weighing Machine 0 to 300 Kg Manufacturing Process The entire process of production begins with the hot-rolled steel section. The resulting product is a strong frame with welded components and ventilators that do not rack. Warehousing and Packaging We adopt the safest and most secured warehousing and packaging practices to ensure our products are well protected during transport and storage. There is as much attention paid to warehousing as in producing the product. For the safekeeping of the finished products, our warehousing facility is well-planned and allows for systematic and regular security checks and orderly storage of products. It is well protected from adverse weather conditions and is therefore ready for supply at all times. Implementing fire safety measures is very important and we conform to all the necessary rules for the same. Our Quality Assurance Our policy is to deliver quality customized products to our clients. Therefore, we implement the most stringent quality regulations on our products to ensure only the best come out of the manufacturing unit. We follow quality measures right from procurement to the production stage without any compromise. We use these parameters to test for quality on our products. Anti-corrosive Long life Accuracy in dimensions Strength At the state-of-the art facility where we have automated processes for manufacturing steel doors and windows, there are built in quality mechanisms that reject doors and windows that do not conform to the dimensions for which they were programmed. Therefore, this ensures that no flawed product passes through the quality control measures. Our Team Our company is a market leader today because of its dedicated and competent professional team. Their superior performance leads to the greater client satisfaction. The team that contributes to our success is: Design engineers Artisans/ Craftsman Quality controllers Marketing and sales personnel Our team is selected on the basis of merit, skills and qualification as well as experience. The team constantly interacts with the clients to ensure that we offer only the best to the client. Client Satisfaction We are the first choice for clients when choosing pressed steel windows because we ensure our product is of the best quality at the best rates. The following attributes have further enabled us to satisfy our clients to the fullest. Sophisticated manufacturing facility Experienced and well trained work force Established, well networked distribution system Customize products to client specification Charges are nominal Delivery of completed products within time slots.