Champion Pharma Machines

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1994

- Business Type:Manufacturer, Exporter

- Main Products:Pharmaceutical Machines, Pharma Machines

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

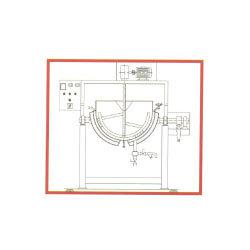

Verify NowRapid Mixer Granulator

Our rapid mixer granulator designed to achieve fast dry mixing, homogeneous binder distribution and making wet granules in the same bowl.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Our rapid mixer granulator designed to achieve fast dry mixing, homogeneous binder distribution and making wet granules in the same bowl. The machine performs mixing and granulation with the help of specially designed mixing bowl, dual speed main impeller, 4 blade chopper very precisely and effectively which leads to faster tableting speeds with improved quality and least rejections. All contact parts made from ss316 / ss304 grade and entire machine designed to confirm cgmp standards. The entire process is fully closed, safe, dust free and automatically discharges the materials.

salient features

specially designed plain mixing bowl provided with counter-balanced lid, vents,view-ports and charging hole.

main impeller consists of dual speed 750/1500 tefc motor coupled with drive mechanism which facilitates inside wash facility for quick change-over and also prevents powder leakage from bottom.

the chopper drive of the rapid mixer granulator consists of dual speed (1440/2800 synchronous speed) tefc motor. The motor shaft is of s. S. And the chopper has specially designed 4 blade s. S. Impeller. The shaft is integral with the motor. The assembly in the rapid mixer granulator is mounted horizontally into the bowl.

discharge port will be provided with pneumatic cylinder. (directly coupled with discharge plug) discharge port provided with 3 position solenoid valve to open and close at desired levels, thereby regulating the discharge and preventing discharge of large lumps.

internal surface of all the vessels will be ground and polished to mirror finish. • mounting structure fabricated of rigid square pipes of m. S. Cladded with ss dimpled sheet & polished to matt surface finish.

control panel

panel board is fabricated from ss304 sheet. The same can be provided as electrical or plc based operation.

panel board consists of relays, motor starter, indicating lamp, ammeter!

voltmeter for both motors, push buttons, controls for discharge!

opening,etc.

digital timer can be provided.

safety features

limit switches are provided on main lid and discharge valve interlocked with control panel for safe operation. + equipment air and purging air control via differential air switches.

optional

flameproof motor with flp push button and flameproof control panel.

bowl can be provided with water jacket and temperature

sensor for product. (as per application).

pneumatic system for opening/closing of bowl lid can also be provided.

a. G. Frequency drive for speed variation of main

impeller motor & chopper motor.

tr-clover ended connection on

top lid for fitting of spray ball for inbuilt cleaning and spray

nozzle for spraying of binder.

wet mill at discharge valve.

note

for rmg-25, which is a lab model - working platform, stair-case and railing is not provided. The operators can access the machine from the ground level of the machine. Also the entire mounting is covered with s. S.

capacity size : from 10kg. To 500kg. (25 ltrs. To 1200 ltrs. )

Images