Champion Pharma Machines

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1994

- Business Type:Manufacturer, Exporter

- Main Products:Pharmaceutical Machines, Pharma Machines

- Reviews & Rating:

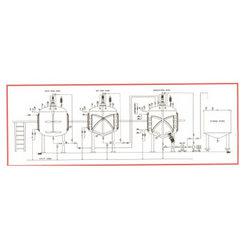

Ointment / Cream Manufacturing Plant

cpm's ointment/cream manufacturing plants are used in the pharmaceutical & cosmetic industries for the production of ointments, creams, lotions, toothpaste, emulsions & homogenizations.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

cpm's ointment/cream manufacturing plants are used in the pharmaceutical & cosmetic industries for the production of ointments, creams, lotions, toothpaste, emulsions & homogenizations. The plant is made with specially designed vessels, pipes, pipe fittings, motors and other accessories. It includes wax phase vessel, water phase vessel, manufacturing vessel, storage vessel, interconnecting piping, bump pump / metering pump, control panel and working platform. The vessels are manufactured from ss316 grade material and are constructed with cgmp compliant. The vessels are jacketed, insulated and cladded. A specially designed agitator assembly is provided in each vessel. Wax is melted and water is heated to desired temperature in the respective vessels and both media will be transferred to manufacturing vessel through vacuum. Both these media are homogenized to make uniform emulsion and cooled by passing chilled water in the jacket of the manufacturing vessel. After the emulsion is formed, active ingredients / colors are added and thoroughly mixed and homogenized. The prepared solution is transferred to the storage vessels by means of a bump pump.

salient features

the complete plant is manufactured under current good manufacturing practice (cgmp).

all contact parts are made up of ss316 and non-contact parts from ss304.

the plant is easy to clean due to complete cover lifting arrangement.

specially designed anchor stirrer with flexible teflon scrapper.

the manufacturing vessel is provided with slow speed anchor agitator for mixing and bottom entry high speed homogenizer for emulsifying.

variable frequency drive is provided in manufacturing vessel for anchor agitator for different speed.

specially designed inline filters can also be provided to ensure proper filtration. (optional)

load cell for accurate weighing online. (optional)

plc based control panel for process automation. (optional)

capacity size : available from 10 kg. To 1000 kg. (20 ltrs. To 2000 ltrs. ).

Images