BTI Machine Tools

Product Range

Fact Sheet

- Location:Punjab, India

- Year of Establishment:1972

- Business Type:Manufacturer, Exporter

- Main Products:Wire Cutting Machine, Wire Straightening & Cutting Machine

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

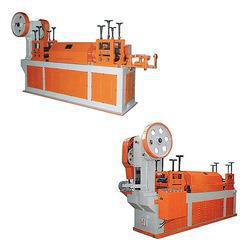

Verify NowStrip Polishing Machine

Leading Manufacturer and Exporter of Wire Straightening & Cutting Machine such as Wire Machinery, Fully Automatic Wire Straightening and Cutting Machines, Heavy Duty Wire Cutting and Wire Drawing Machinery, Ribbed Wire Straightening & Cutting Machine

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

The Strip Polishing Machine comprises a one piece electro welded bench with a ground surface incorporating special interchangeable wear-resistant stainless steel plates which ensure a perfect level surface over time.

Over the bench runs a special conveyor belt which has been stiffened to avoid jerking movements. The belt is driven by means of a motor reduction unit linked to an inverter and its speed is accurately monitored by an encoder mounted on the idle roller.

The spindle groups are housed in the centre of the spindle bridge (a large electro welded steel structure) so as to ensure maximum stability.

Inside the spindle groups are chromed sleeves for the vertical movement of the abrasive heads.

The bridge rests, by means of a hinge, on sliding blocks which move on ground roller ways lubricated in an oil bath and are sealed by stainless steel labyrinths. An intermediate support has also been added so as to eliminate any bending of the bridge.

This is also oil-bath lubricated with stainless steel labyrinths. The group is powered by a motor reduction unit, the speed of which is regulated by an inverter. The racks and pinions have sloping teeth in order to ensure the smooth running of the machine. The vertical movement of the polishing heads is performed by a pair of pneumatic cylinders working in counter pressure. The polishing heads are separated from one another by a metal diaphragm complete with a rubber strip which stops grains of abrasive from the previous heads from cutting the polished surface.The machine has single doors in stainless steel so as to be able to change the abrasives one by one.

The polishing machine may be equipped with a centralized automatic lubrication system which can be programmed so that all the parts are correctly lubricated.

Images