Bharat Industries

Product Range

Fact Sheet

- Location:West Bengal, India

- Year of Establishment:1987

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Main Products:Chain Pulley Block, Lifting Equipments

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowReduction Gear Box

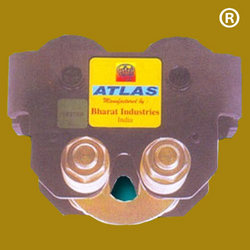

We are engaged in offering our clients Reduction Gear Boxes which are availed by our customers under the brand name ATLAS.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We are engaged in offering our clients Reduction Gear Boxes which are availed by our customers under the brand name ATLAS. These are single reduction worm gar units available in different sizes and adapted to various industries as per their requirements. The following are general features of our Reduction Gear Boxes: Robust Construction Increased efficiency Flexibility Interchangeability Compactness Dependability Reliability. The other features and specifications of components are as follows: Selection: Please refer Horse Power Rating Table and determine the size of the particular unit either by way of input horse power or output torque. The Ratings are based on Unity factor of 12 hours continuous running under uniform load subject to recommended lubrication and temperature limitation of 90 degree C. Gear Housing: Gear Housing is made of close grain top quality cast iron liberally designed to Store adequate quantity of oil so as to achieve higher thermal ratings. It is provided with large cooling fins on both sides with maximum surface area exposed to atmosphere for improved efficiency. Bearing Housings are perfectly bored to ensure perfect alignment. The housing is totally dust proof and oil tight. Worm: Worm and worm shaft is of single piece accurately made out of high grade alloy steel and is highly polished. Worm Wheel: The worm wheel is made of cast phosphorous Bronze rims are shrunk and screwed on central cast iron boss. Teeth are accurately hobbed by generating process. To facilitate interchangeability, each worm wheel is inspected to match the master piece. Bearings: The worm and worm wheel shaft are supported on ball or roller anti friction bearings of ample capacity to permit over hung and shock loads. Shaft: Shaft is made of high grade alloy steel suitably designed to withstand high torque and bending loads. Oil Seals: Superior quality oil seals are used to ensure complete oil tight. Lubrication: Gears and bearings are automatically and positively lubricated at all speeds by splash of oil from the sump. Thus no special attention is necessary expect periodically checking the oil level. Cooling: Heat dissipation is effectively controlled by increased oil capacities and a large gear case surface area exposed to air. The fan mounted on the worm shaft induces continuous air flow which increases heat transfer for improved efficiency. Efficiency: Higher efficiency is achieved by correct design, careful selection of material, efficient lubrication and through inspection. Every Gear is checked for silence and oil tightness.

Images