Ashtech India Private Limited

Company Overview

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:1997

- Business Type:Manufacturer, Distributor / Wholesaler, Exporter

- Turnover:Rs. 50 - 500 Crore

(or USD 10 Million - USD 100 Million) - Main Products:Fly Ash, Super Pozz

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

Verify NowCompany Info

Overview

Ashtech's commitment to uncompromising quality, responsive service, competitive pricing through continuous innovation in process, productivity, motivated work force, efficient marketing and wide distribution network keeps us ahead of our mission to excel in our chosen field.

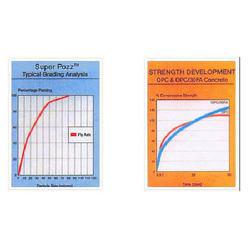

Ashtech's Fly Ash is among the first Classified And Processed material being made available in India. By classifying and processing, we ensure that our Fly Ash is consistent and in compliance with the most stringent specification requirements of various international codes of practice such as BS 3892 Part 1, ASTM C 618 Class F, EN 450 And IS 3812 Grade 1.

Our customers can, therefore, be assured of the highest standards of quality, process control and product consistency.

Benefits of Fly Ash Usage

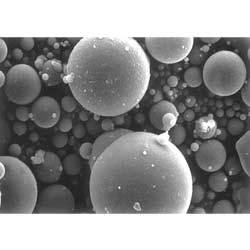

Fly ash is a bi-product of coal based thermal power stations generated by the combustion of pulverized coal. It is a pozzolanic material rich in silica & alumina and spherical in shape. The commonly known benefits of using fly ash in concrete are:

Workability

Reduced permeability

Reduced heat of hydration

Improved pump-ability

Improved sulphate and chloride resistance

Reduced risk of alkali aggregate reaction

Increases long term strength

Better concrete finish

Reduced bleeding and segregation

Reduced shrinkage and many more

Green Benefits

Today, fly ash is one of the greatest energy saving resource and as a recycled material, it creates significant benefits for the environment. Harmful CO2 emissions or greenhouse gases are reduced when fly ash is blended with cement or used as a cement extender in concrete applications. For every ton of cement replaced by fly ash, it enables less energy to be consumed and there is a marked improvement in the environmental footprint of the concrete.