Ashok Industries

Product Range

Fact Sheet

- Location:Gujarat, India

- Year of Establishment:1972

- Business Type:Manufacturer, Distributor / Wholesaler, Business Services

- Turnover:Rs. 50 Lakh - 5 Crore

(or USD 100 K - 1 Million) - Main Products:Paper Machine, Waste Paper Recycling Plant

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

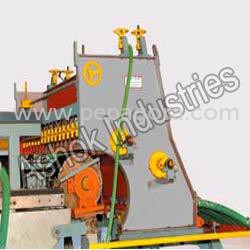

Verify NowPope Roller

M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm. Pope Roller For Paper Making Machine M. S. fabricated drum & C. I. framing. Reeler is designed on the principle of circumferential winding. We will provided auxiliary (Primary) arms is pnumatically operared for loading & mechanical arrangements for shifting of reel. Working (Secondory) arms is loaded for pnumatically. Before the reeler camber pipe or camber roll are installed for creasing free realling. Having pneumatic loading arrangements which ensures tight reeling and automatic reeling change over system which readuces the loss during the change over. Maximum paper real Dia 2000 mm.

Images