Ammech International

Product Range

Fact Sheet

- Location:Maharashtra, India

- Year of Establishment:2005

- Business Type:Manufacturer, Exporter

- Main Products:Box Furnace

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

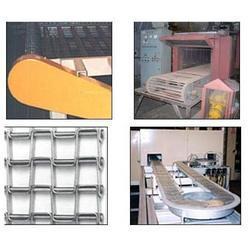

Verify NowDrop Bottom Ovens

We are engaged in offering quality range of drop bottom furnaces, ovens popularly known as elevator ovens. These ovens are specially designed for aluminum or non-ferrous metal solution heat-treating. The incorporated state of the art insulation.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We are engaged in offering quality range of drop bottom furnaces, ovens popularly known as elevator ovens. These ovens are specially designed for aluminum or non-ferrous metal solution heat-treating. The incorporated state of the art insulation, control system and hoist mechanisms ensure optimum performance and reliability of the oven. We can fabricate drop bottom furnaces in electric, gas fired, or indirect gas fired configurations as per the requirement. We offer temperatures to 650°C with uniformity of+/- 8°C.

Working procedure:

The product, often loaded in baskets or on a grid, is positioned under the oven and is attached to a lift mechanism

The load is then lifted into the chamber and the doors, located on the bottom, are closed

The oven then proceeds with the heat-treat of the load. At a prescribed time, the doors open, and the load is lowered at a near free fall rate into a waiting quench tank

For solution treatment of aluminum extrusions, sheet metal, castings and other parts, we offer drop bottom furnaces, quench tanks, age ovens and related equipment. We offer complete installation services, from startup assistance to complete turnkey installations. These ovens are known for low maintenance and optimum performance and efficiency.

Rugged Construction:

The drop quench ovens are fabricated for an intensive and continuous use up to 650o C

The dual speed electromechanical winch system allows controlled acceleration/deceleration of the load descent. This has proven to be more reliable and sturdy than the frequently used pneumatic systems

Images