Abs Water Tech India Pvt Ltd

Product Range

Fact Sheet

- Location:Tamil Nadu, India

- Year of Establishment:2011

- Business Type:Trading Company, Distributor / Wholesaler, Exporter

- Main Products: Water Treatment Plants, Water Treatment Chemicals

- Reviews & Rating:

Get Verified, Sell more with

- Buyer's trust

- Faster conversions

- Better Rankings

- More

Its Free

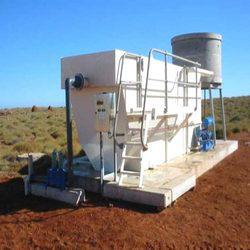

Verify NowWastewater Treatment Plant - Zero Liquid Discharge Systems

We offer a wide range of Zero liquid dischrge systems for treat the various industries waste water like cooling tower blow down water,dyeing unit water,steel industries,petro chemical industies waste water,sugar industires water.

- FOB PriceNA

- Min Order QuantityNA

- Payment TermsNA

Other Details

We offer a wide range of Zero liquid dischrge systems for treat the various industries waste water like cooling tower blow down water,dyeing unit water,steel industries,petro chemical industies waste water,sugar industires water.

Various range of cpacities from 25 KLD to 10 MLD.

Waste water could be recycled for thier process and utility purposes.

The size of the RO and choice of membrane will be determined by the permeate quantity required, feed water salinity and permeate quality expected. Low energy membranes allow the units to run at pressures around 150-200psi, and as such the pressure booster pumps required to generate the pure water are smaller, and the power consumption is reduced significantly.

Features:• Demineralized water without acid & caustic regenerants

• Removes pyrogens and bacteria

• Low operating costs

• No effluent neutralization required

• No regeneration down time

• No handling with hazardous regenerants

• Electronic quality control

• Corrosion resistant material of construction

• Compact design

Principle of operation Pretreated water is pumped into the membrane housings along the membrane surface. Pure water is permitted to pass through the membrane while ionic, organic, colloidal and bacterial contaminants are swept away in a concentrated solution.

Consequently, a reverse osmosis system always creates two continuous exit streams: pure water (permeate) and brine (concentrate). Normally 50 to 75 percent of the feed water can be recovered as permeate.

System design In order to protect the RO membranes against foulants a complete system usually consists of a softening plant and a reverse osmosis unit equipped with a prefilter. An activated carbon filter has to be added if free chlorine is present in the feed water. To further improve the water quality in terms of conductivity the permeate can be polished downstream.

Quality

An Instrumech reverse osmosis unit will usually retain 95 to 99% of all inorganic dissolved solids and more than 90% of all organic contaminants. Carbonic acid, however, will penetrate through the membrane into the permeate.

Membranes

The membranes are of Thin Film Composite (TFC) type and packed in a spiral wound module configuration. TFC membranes have high salt rejections and good performances under wide-ranging pH and temperature conditions. They are not degradable by microorganism and hold their productivities over long periods of time.

Advantages

• Water containing a high level of natural salts can be purified without the need for chemical regenerants such as the acid and caustic used in demineralisation plants.

• Safer route of producing pure water for many commercial and industrial applications.

Our clients can avail from us Wastewater Treatment Plant - Zero Liquid discharge systems, these waste water treatment plants and zero liquid discharge systems find applications in various industrial establishments to remove impurity from waste water. To provide our clients with the satisfaction they desire, we always offer them with innovative and latest technology incorporated machinery products.

Product Application

• Hospitals and dialysis centres

• Public and private laboratories

• Process water for food and drink industries

• Process water for pharmeceutical and chemical industries

• Process water for metal finishing and paint industries

• Rinse water for the production of electronics, glass and mirrors

• Cooling and boiler feed water

• Feed water for humidification

Images